Bending LED Light Extrusion Profiles

Aluminum LED Light Profile Bending Process

In the field of LED lighting, precision, design, and functionality go hand in hand, and BIT not only provides high-quality aluminum bending machines for LED Light Extrusion(LED Lighting Frame Bending Machines), but also advanced tool design and technical support for bending and twisting.

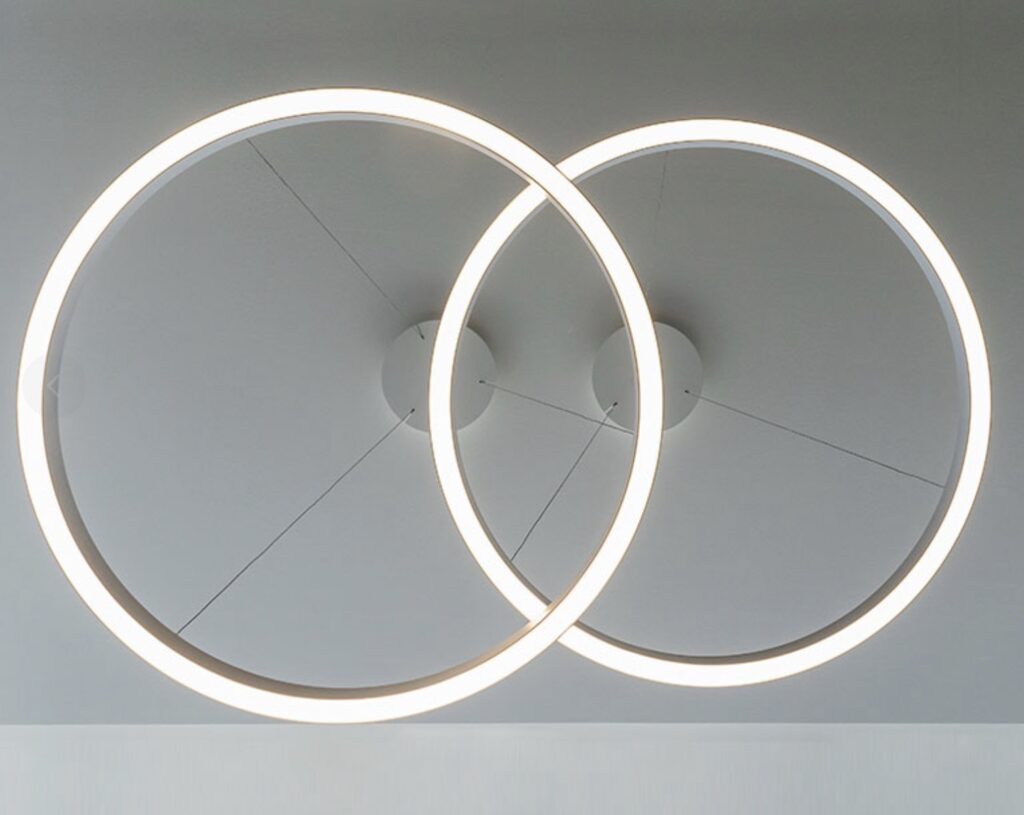

About Curved LED Profiles

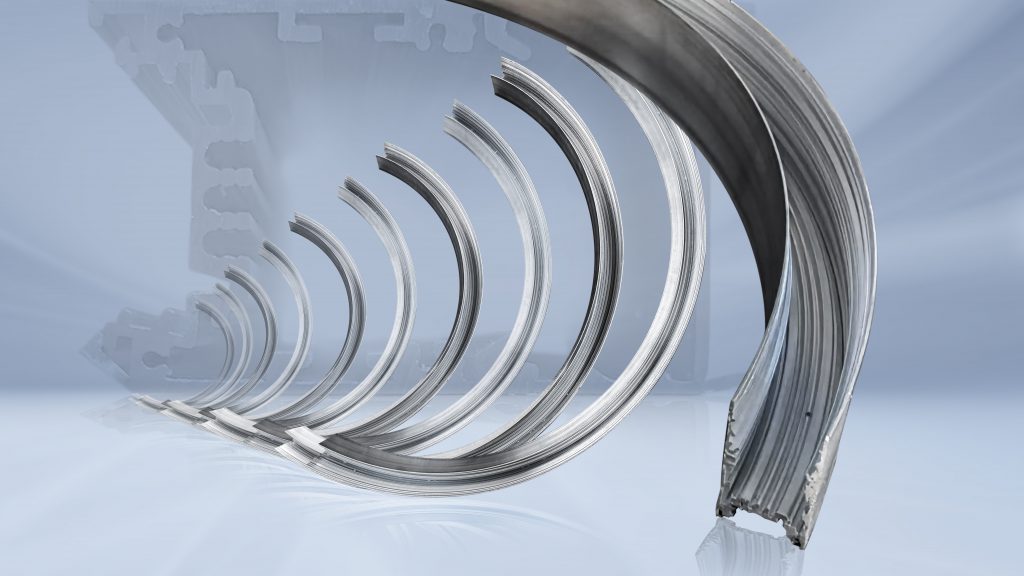

Curved LED Profiles are designed to protect and enhance LED strips while maintaining a sleek appearance. Their unique curved shape offers a smooth, seamless finish, ideal for spaces requiring a refined lighting touch.

These profiles are bendable, making them perfect for illuminating curved surfaces like pillars, arches, and walls. Their flexibility supports various lighting designs, such as cove, arc, and S-shaped lighting.

Additionally, Curved LED Profiles help dissipate heat, extending the life of LED strips. They are ideal for both indoor and outdoor projects, providing endless possibilities for creative lighting solutions.

Bending Process

The LED Light Profile Bending process allows the shape of the lamp to be customized according to specific project needs. This allows LED manufacturers to create custom shapes that perfectly match the architectural style of the interior or exterior facade. Bending not only improves the aesthetics, but also enhances the functionality of the lamp, allowing the light to shine precisely where it is most needed. Depending on the model, LED Light Extrusion can be bent downwards, inwards, outwards, or even in all directions. In addition, some LED profiles can be twisted (PBA 3D bending machines can provide this special customized device), providing more design possibilities.

- Cover down (X-X axial bending): specially designed for LED Light Extrusion cover downward bending. This bending method is ideal for applications that require a delicate and elegant light on the ceiling or wall.

- Cover facing inwards or outwards (Y-Y axis bending): LED Light Profile Bending requires bending inwards or outwards. Bending inwards is usually used for projects that require light diffusion, while bending outwards can create dynamic spatial compositions.

- Profiles bent and twisted in all directions (T-axis bending/Twist axis, or off-axis bending): Some special projects require LED light profiles that are bent or even twisted in all directions (such as PIKO-ZM or GIZA-DUO-LL). LED Light Extrusion requires bending and twisting in any direction (forming spirals or waves) to create unique luminaires.

Minimum Bending Radius (Important Details)

Each of the bending or twisting aluminum LED light profile bending processes described above has a specific minimum bending radius.

Now, you can access top-notch service from BIT’s engineers, who bring over 20 years of unrivaled experience in aluminum profile bending tool design.

Enhancing Bending Stability for LED Light Extrusions

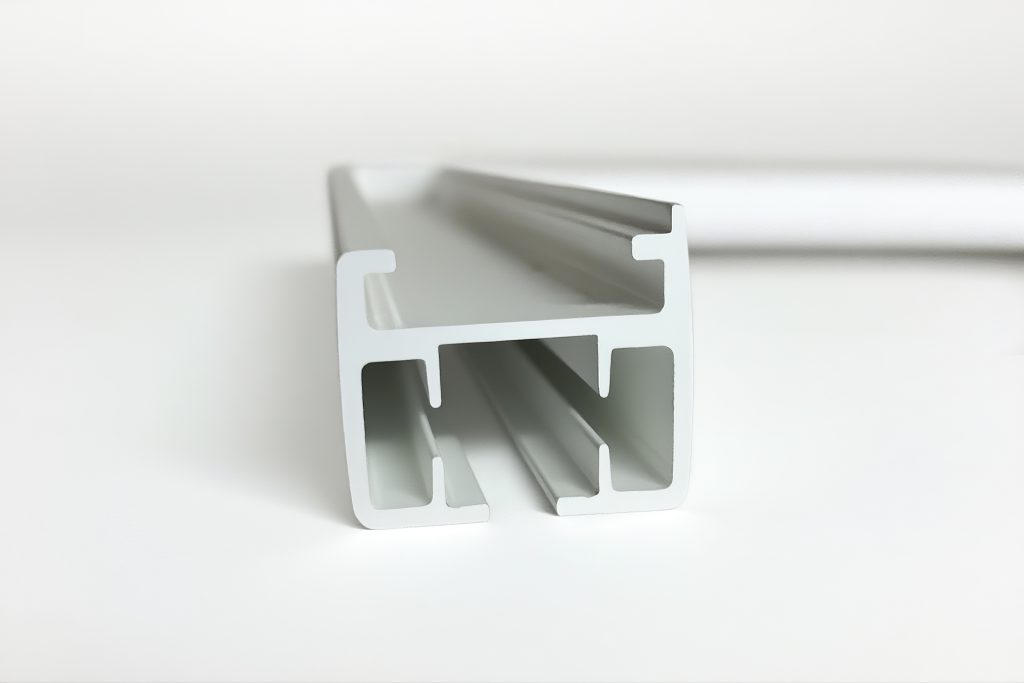

When planning LED light manufacturing, the first consideration is which design features make bending LED light extrusion easier.

If the LED light extrusion design cannot be changed, what can we do to improve its bendability?

Like other bending aluminum profiles, LED light extrusion is typically a U-shaped channel with a highly asymmetric design. This asymmetry causes significant torsional forces during bending, leading to the side legs twisting toward the channel’s centerline.

Structural Modification for Improved Bending

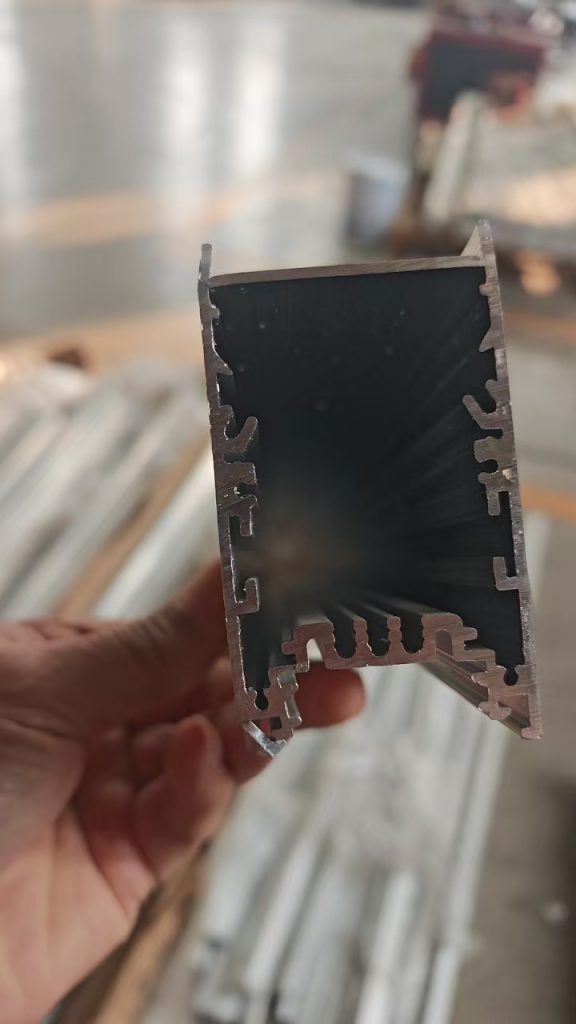

To address this, we can modify the LED light extrusion’s structure to correct the severe asymmetry. This adjustment reduces torsional stress during bending. Below is a case where we successfully bent an LED light aluminum extrusion for a customer, effectively eliminating the negative effects of bending.

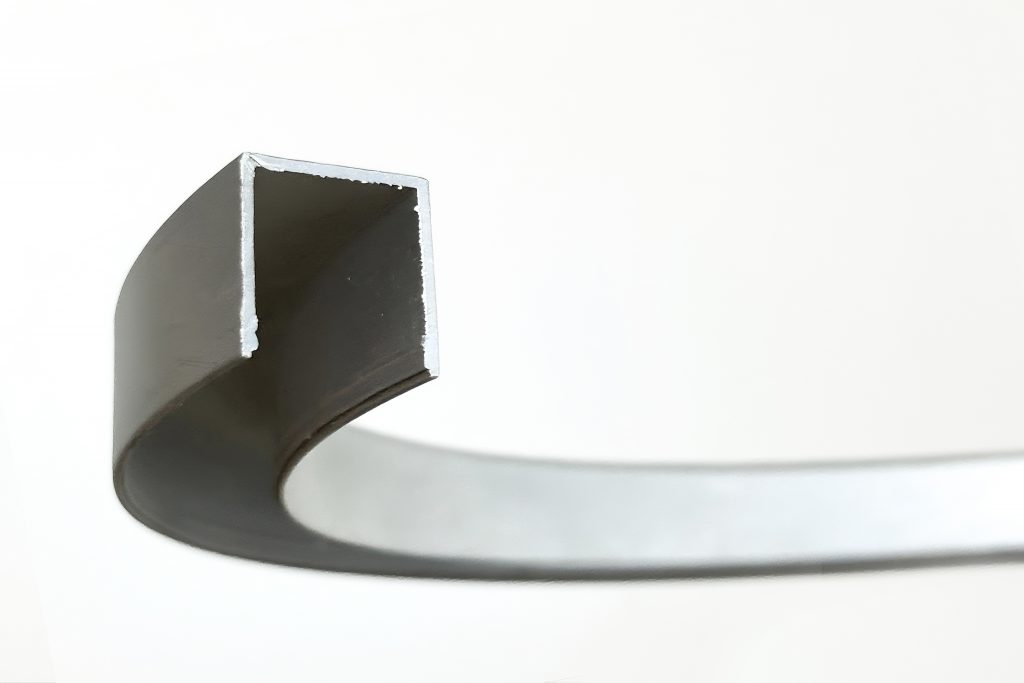

Preventing Twisting with a Temporary Connection Piece

As shown in the image, the bent LED light aluminum extrusion remains free from twisting. The solution was to add a temporary, removable connection piece at the channel’s opening, as illustrated in the following gallery. This structural enhancement improves stability during bending and prevents deformation. Once bending is complete, the connection piece is removed.

Considerations for Assembly and Clearance

Another key consideration in bending LED light extrusions is their intended fit within an assembly or their ability to move freely inside a housing. Therefore, design specifications must include clearance tolerances to ensure proper installation and functionality.

When Modifying the LED Light Extrusion Structure Is Not an Option

In reality, modifying the structure of an LED light extrusion is not always feasible. Various factors may prevent any major changes to its design.

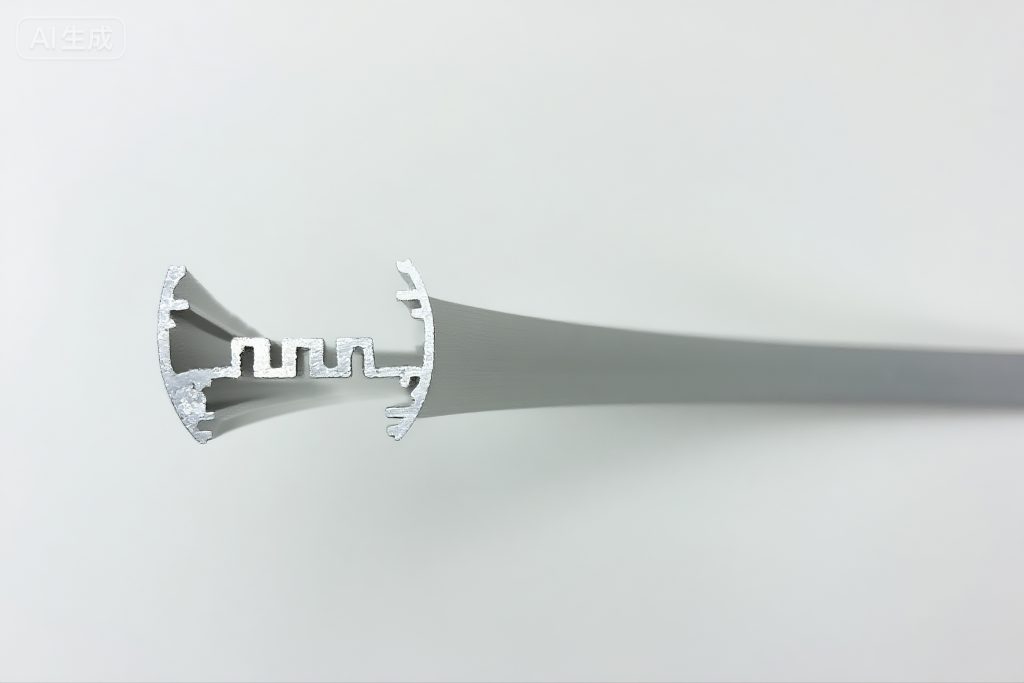

For aluminum LED light extrusion bending, the PBA aluminum bending machine is a large-radius profile bending solution. Additionally, BIT engineers provide technical support by designing internal support profiles for customers. These supports are typically made from polymer materials and help maintain stability during bending.

As shown in the two videos in this article, both cases utilized internal support profiles. Notice how the internal support ensures sufficient symmetry in the LED light extrusion, effectively eliminating the significant torsional forces that negatively impact aluminum bending.

Right Temper: Avoid Cracking During LED Profile Bending

LED aluminum extrusions are often lightweight and thin-walled. If the material hardness is too high, bending can easily cause cracking. Therefore, selecting the right temper is critical. For most applications, T5 temper offers a good balance between strength and bendability, making it the preferred choice for bending LED profiles.

PBA LED Lighting Bending Machines

The PBA aluminum bending machine offers unparalleled precision for shaping Curved LED Profiles. It excels in handling Single Curves, Complex Multi-Arc Shapes, Reverse Bends, and End-to-End configurations, ensuring versatility in lighting design. With its advanced control system, the machine delivers smooth and consistent results, maintaining the structural integrity of the aluminum profiles.

Whether you’re creating simple curves or intricate multi-arc shapes, the PBA machine allows for accurate adjustments to match various design needs. Its ability to perform reverse bends and achieve seamless end-to-end connections makes it perfect for challenging architectural projects.

This flexibility makes the PBA aluminum bending machine an essential tool for lighting professionals, enabling them to create unique, fluid lighting solutions for both indoor and outdoor applications.

Top 3 Important Factors for Perfect Aluminum Bending With PBA

- PBA aluminum bending machine’s unique CNC operating system addresses springback in two steps: input the actual radius to get the coefficient, then input the compensation coefficient and start production.

- PBA’s aluminum bending machines utilize a combination of motion controllers and servo motors to ensure precise repeatability of aluminum bending workpieces, with a repeat position accuracy of ≤0.01mm.

- Now, you can access top-notch service from BIT’s engineers, who bring over 20 years of unrivaled experience in aluminum profile bending tool design.

BIT is China’s leading company in aluminum profile bending machines, ensuring high-quality results that enhance both the aesthetic and functional aspects of your projects. Our PBA aluminum bending machine excels in providing flawless bending for LED fixtures, allowing for smooth and seamless designs.