Aluminium Window Bending requires skill, but with BIT’s free tooling design service, the process becomes effortless.

Curved aluminum alloy windows offer unique advantages, effectively enhancing spatial aesthetics. Compared to regular windows, the bending process is more challenging. Therefore, high-quality aluminum profile bending machines are essential to avoid cracking during aluminium window bending.

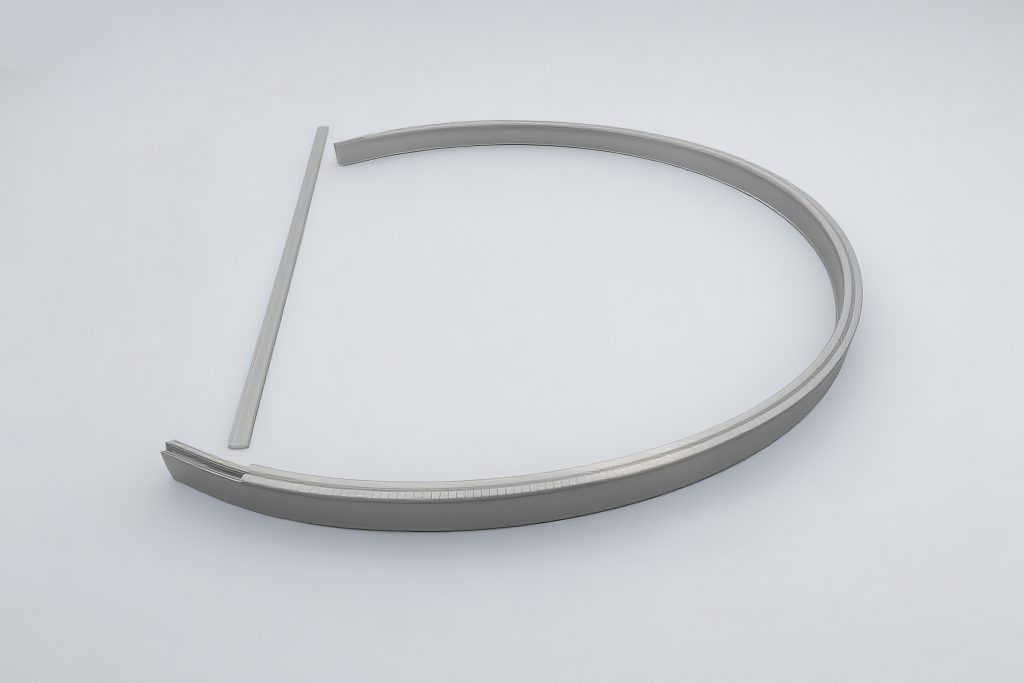

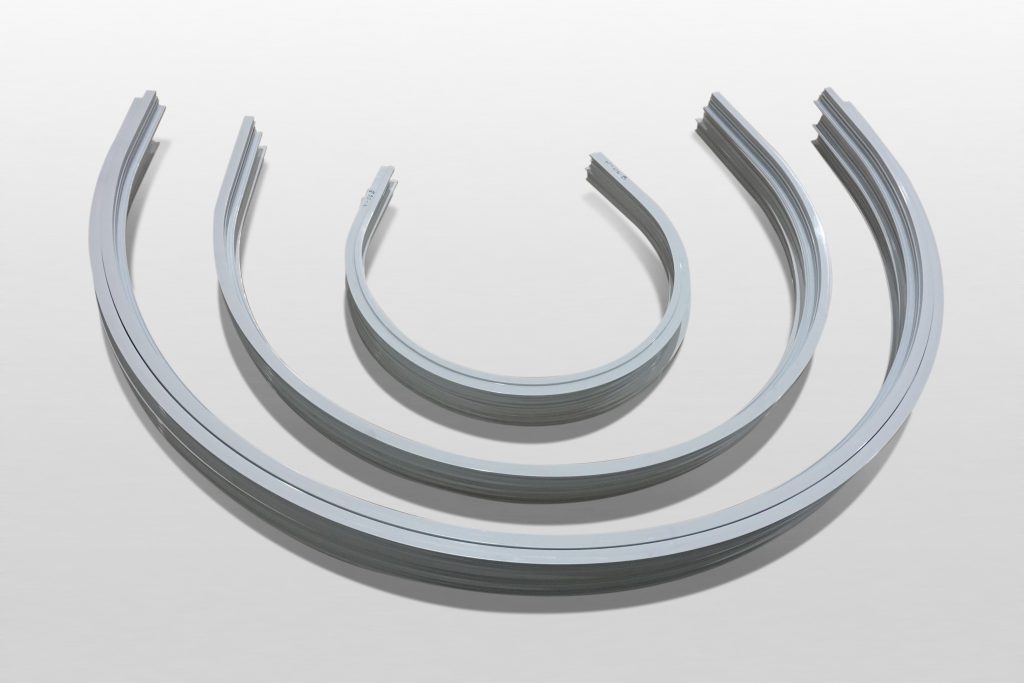

Aluminium Window Frames Bending

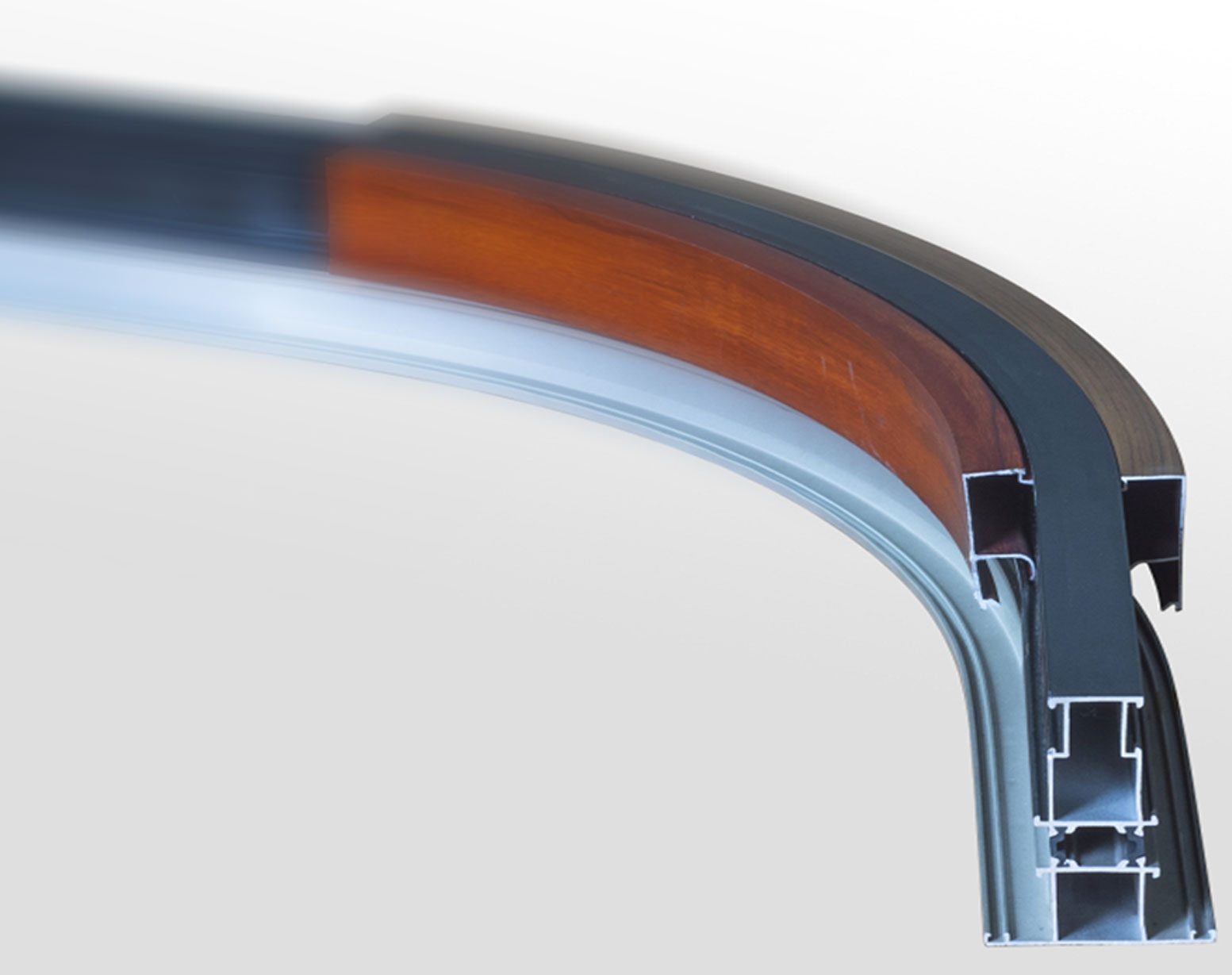

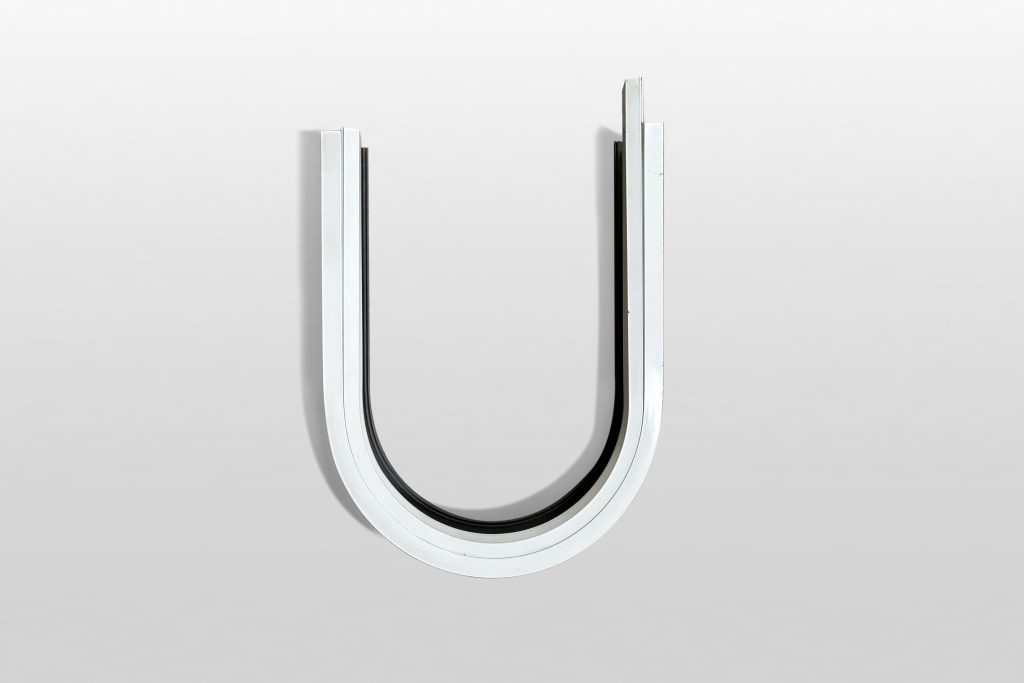

Our PBA aluminium bending machines deliver precise bending solutions for aluminum window profiles, meeting diverse design needs with flexibility. With PBA machines, you can create arched windows with inner bends, Gothic arches with tight curves, and circular or elliptical portholes. Typically, aluminum sections are bent before painting to avoid scratches or marks on the powder-coated surface. Notably, BIT incorporates protective coating processes during tooling design to minimize the risk of damaging coated sections during bending.

Please note the roll bending of curtain wall materials in the video on the right. BIT’s innovative tooling design prevents surface damage during the bending process.

Aluminium Window Bending Processes

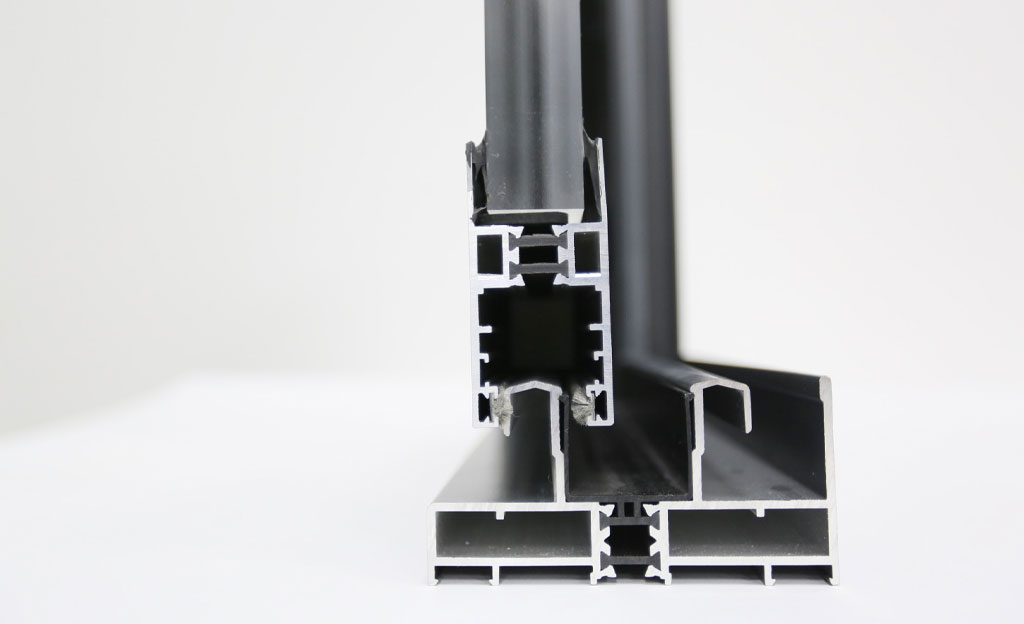

Roll Bending Process:

Roll bending shapes window aluminum profiles using a multi-roll bending machine along a single axis. When the semi-finished product remains stationary during bending, the distance between rollers, roller diameter, and depth of penetration determine the bending radius. For larger bends, the material is alternately moved through the aluminum roll bending machine, with the distance between the upper and lower rollers gradually adjusted to achieve the desired radius.

Stretch Forming Process:

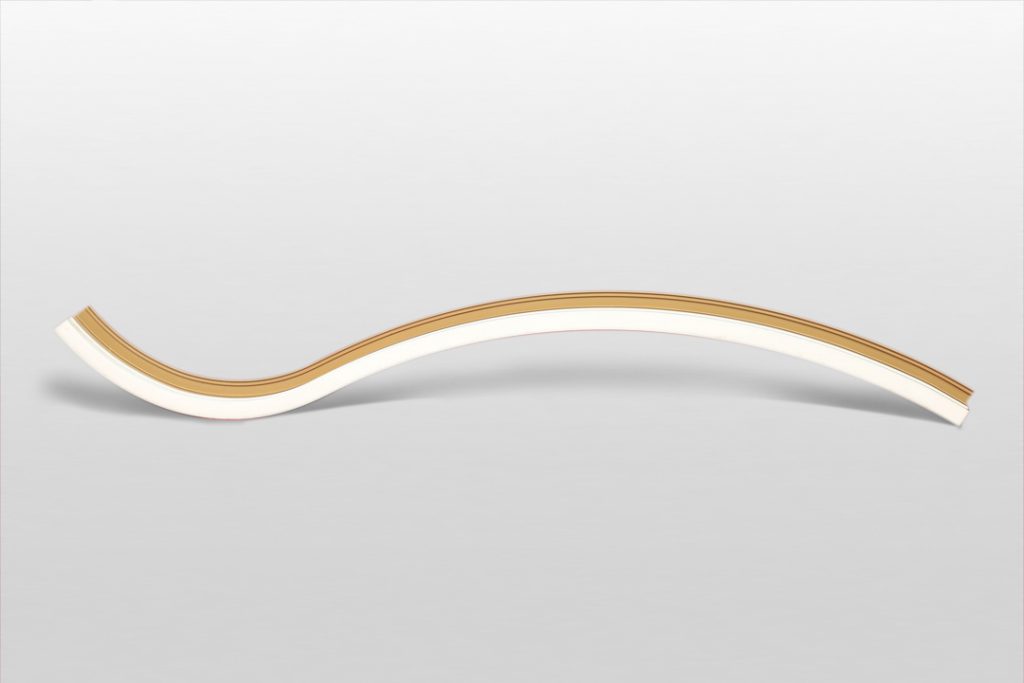

In stretch forming (also called stretch bending), the profile is clamped on both sides and stretched during the bending process. Under combined bending moments and longitudinal tension, the aluminium window profile is pressed into the mold groove to achieve the desired shape. This gentle process reduces the formation of cracks or pressure points at bending areas. Stretch forming provides precise shaping allowances, improves manufacturing accuracy, and lowers production costs. It is ideal for producing large, high-precision, variable-curvature parts with relatively large bending radii.

Note: When using the stretch bending process for window aluminium profiles, anodized or coated sections can typically be bent post-treatment. Since no relative movement occurs between the profile and the mold during stretch bending, the profile remains undamaged.

Aluminum Profile Bending Radius Calculator

Protects Powder-coated Surface

Aluminium window bending can sometimes be the simplest way to work with aluminum profiles, but it can also be quite complex. Additionally, there is a risk of damaging the surface quality of pre-coated profiles. To address these additional risks, special measures must be taken to protect the surface of coated profiles. Using high-quality tools can effectively prevent damage.

The video on the right showcases beautifully bent profiles that remain intact after powder coating. Although bending after powder coating and achieving very tight radii is challenging, PBA can almost meet any aluminum bending requirement.

Five Key Requirements Before Aluminium Profile Bending

- Material Length:

Prepare material with a total length equal to the effective arc length plus the process section. The process section is 2.1 times the deformation width (t), where t=Router−Rinner. Thus, the preparation length is calculated as:

Preparation Length=Effective Arc Length+2.1t

To save material, consider nesting and optimizing the length based on actual requirements. - Material Quantity:

For aluminum window bending, prepare 1–2 extra pieces in addition to the required quantity for different cross-sections, radii, and arc lengths. These extras are used for mold debugging. Note: This does not account for potential losses during transportation, processing, or installation. - Effective Arc Length:

Typically, the effective arc length for aluminium window bending should not exceed 180 degrees (stretch forming). - Hardness State:

Choose T5 temper when the aluminum’s elongation rate satisfies deformation requirements (δ≤10%), per Chinese national standards(δ≥8%). The aluminium window bending formula is:

δ=t/Rinner×100%=[(Router−Rinner)/Rinner]×100%

If this is not achievable, select temper T0 to T4 instead. - Surface Treatment:

For aluminium window bending, anodizing or coating is typically performed post-bending. The coating’s elongation rate greatly exceeds that of the profile, reducing the risk of surface damage.

Read More: Key Factors for Aluminium Window Bending

Further Reading: Curved Aluminium Windows

The advantages of curved aluminum windows include unique designs, enhanced functionality, and easier installation. They maximize natural light, reduce energy consumption, and improve building aesthetics. PBA aluminium profile bending machines support bending multiple aluminium window bending, perform axial bending of thermal break sections, and handle any extrusion size, meeting various radius requirements.

- Axial bending of thermal break sections: Ensures material strength and stability during processing.

- Bending of any aluminium window profile size: Capable of handling various aluminum profile sizes to meet diverse design requirements.

- Multiple radius options: Supports versatile designs, suitable for different architectural styles.

- Bending of irregular façade aluminum window profiles: Precisely handles complex shapes, enhancing building aesthetics.

We also have solutions for UPVC window profile bending: the customized PBA-500+ aluminum profile bending machine ensures consistent precision in bending PVC window profiles.

Choose PBA aluminum bending machine for aluminium window bending for high-quality, personalized services that ensure the success of your project. Get in touch with our team on WhatsApp at +86-1775-1300-713 or E-mail: [email protected] and we’ll find the right solution for you!