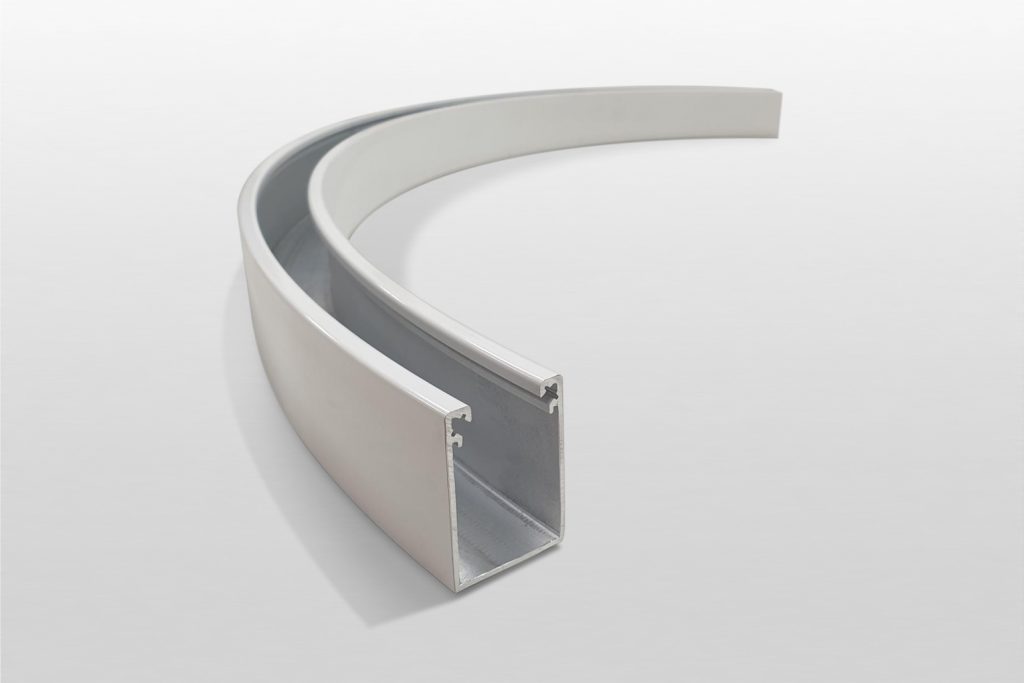

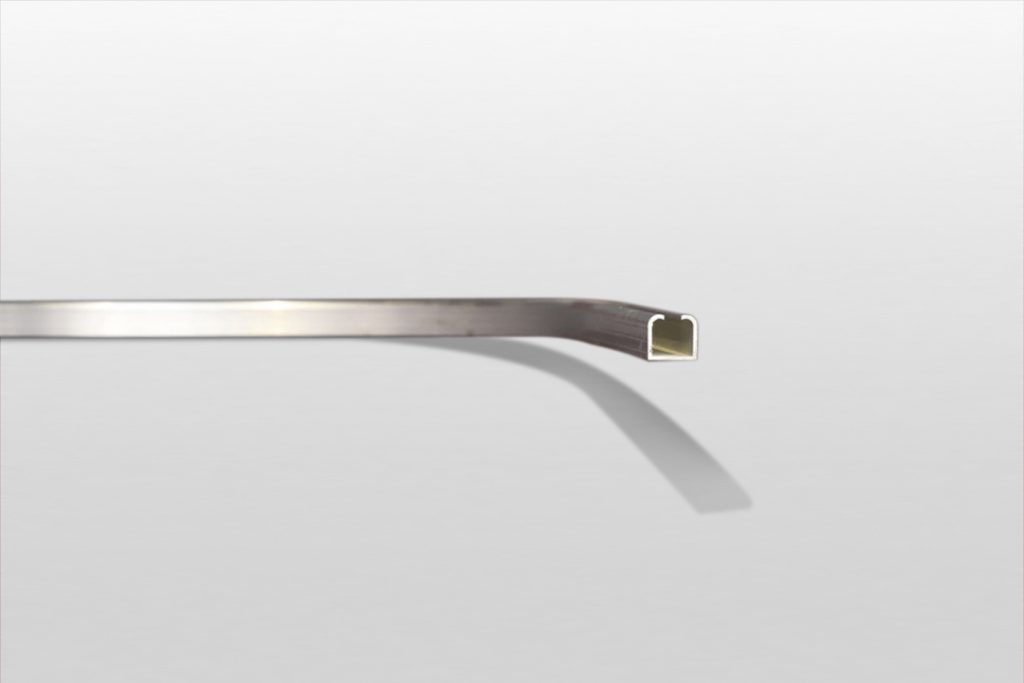

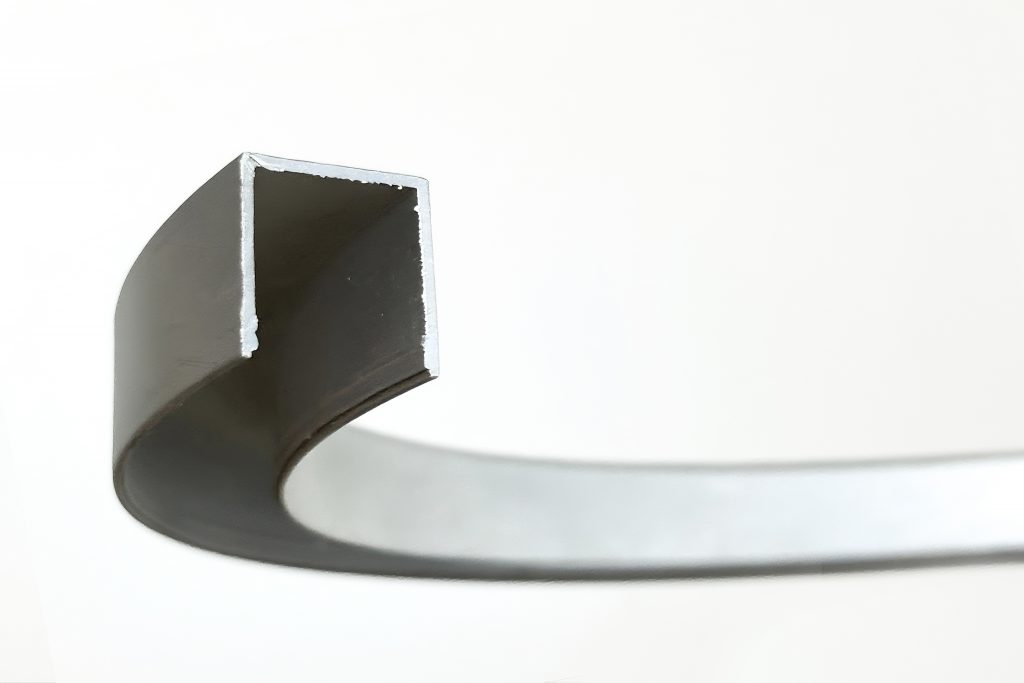

In our work, we often encounter the need to bend and form special channel aluminum or steel profiles with the PBA aluminum profile bending machine. These profiles typically have an open cross-section, shaped like the letters “C” or “U”, and are therefore commonly referred to as U-channel or C-channel.

They not only offer good structural strength and bending resistance but also maintain lightweight properties while meeting various assembly and connection requirements. Due to their high versatility and customizability, these profiles have become common materials in modern mechanical manufacturing, building structures, electrical installations, and transportation equipment.

Applications of Bent U-Channel and C-Channel Aluminum or Steel

These U-channel and C-channel aluminum or steel profiles, produced through bending processes such as roll forming, stretch forming, or press forming, feature high structural strength, low weight, high dimensional accuracy, and easy assembly. As a result, they are widely used across multiple industries.

- In the lighting industry, they are often used as LED lamp housings, brackets, and installation tracks, combining both aesthetics and functionality.

- In electrical and wiring systems, U- and C-channels serve as the main structural materials for cable trays, wire protection channels, or distribution supports, providing both support and protection.

- In building and interior decoration, these profiles are widely applied in curtain wall frames, ceiling supports, partition system tracks, and window and door frames, ensuring structural stability while offering installation flexibility.

- In furniture and home systems, C-channel tracks can be used as sliding tracks and support components for sliding doors, storage systems, or modular shelving, reflecting modern design efficiency and simplicity.

- Additionally, in transportation and vehicle manufacturing, U- and C-channels are commonly used in the frames, guides, and protective structures of automobiles, trucks, and high-speed rail vehicles, meeting the dual requirements of high strength and lightweight.

- In renewable energy and industrial equipment, these profiles are widely used for solar panel mounts, wind turbine frames, control cabinets, and machinery supports, providing a reliable foundation for industrial assembly.

Bending Direction and Material Yield Strength

Our channel aluminum or steel profile bending process (also referred to as U-channel or C-channel forming) is influenced by multiple factors, including material type, thickness, part geometry, and most importantly, the bending direction (easy way / hard way).

In the easy way, the bending direction aligns with the channel opening, making deformation easier and requiring less bending force.

In the hard way, the bending direction is perpendicular to the opening, and the material’s resistance to deformation is higher, requiring higher tonnage equipment, precise dies, and stricter process control.

In addition to bending direction, material yield strength and heat treatment state (such as T4, T5, T6) have a decisive impact on bending performance:

- T4 (naturally aged): Yield strength generally ranges from 150–220 MPa, with good plasticity and ductility, suitable for large-radius bends or profiles with high surface quality requirements.

- T5 (artificially aged and cooled): Yield strength around 200–260 MPa, balancing strength and bendability, commonly used for lamp frames, tracks, and automotive structural components.

- T6 (artificially aged and strengthened): Yield strength typically 250–320 MPa, with lower ductility, requiring higher tonnage or pre-bend adjustments to prevent cracking.

For high-strength aluminum alloys, stainless steel, or carbon steel profiles, yield strength can reach 500–900 MPa, necessitating more complex multi-step forming processes and equipment control.

Cold Bending Processes for Aluminum or Steel U- or C-Channel Profiles

Depending on material and structural requirements, we employ various bending and forming processes:

- Roll Bending / Profile Bending: Suitable for long or continuously curved profiles, widely used for C- and U-channels, rails, and cable trays.

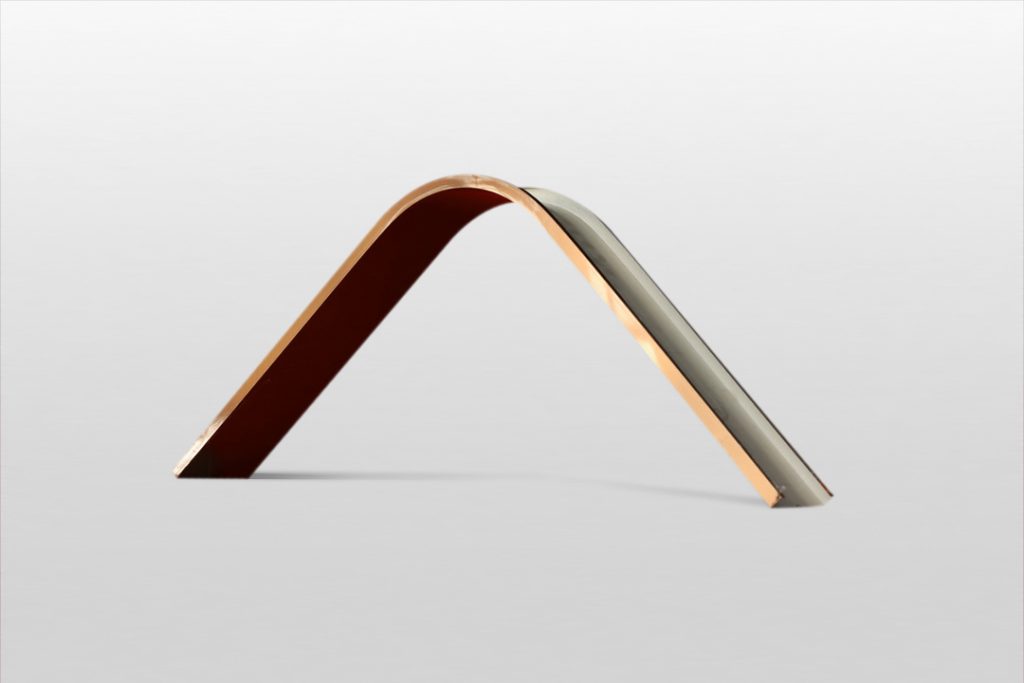

- Stretch Forming: Combines tensile and bending deformation to achieve high-precision curvature, commonly used in rail transportation, automotive bodies, and architectural curtain walls.

- Press Bending: Used for medium or high-strength materials to achieve precise shaping, ensuring consistent cross-sectional dimensions and structural stability.

By comprehensively analyzing and controlling material condition, yield strength, bending direction, and process parameters, we can achieve high-precision forming for a range of components, from flexible decorative parts to high-strength structural elements, providing customers with stable and reliable channel steel bending solutions.

Bending C & U Channel Aluminum or Steel Profiles with PBA Bending Machine

The most common bending method is a roll bending with PBA aluminum bending machine.

The simplest bending technique for aluminum C or U channels is “flange-out.” “Flange-in” channel bending can be more challenging if the flanges are relatively high.

The simplest bending technique for aluminum C or U channels is “flange-out.” “Flange-in” channel bending can be more challenging if the flanges are relatively high.

The most challenging channel bending technique is the “hard” bending technique. In fact, all other things being equal, hard bending is one of the most difficult structural shapes to bend without deformation. These profiles can typically be bent using a filler tool or by modifying the cross-section shape and adding a temporary connection piece. Removing the temporary connection piece after bending can achieve perfect bending results.

Place an aluminum C or U channel filled with tool strips (to prevent cross-sectional deformation, the tool strips are required depending on the cross-sectional shape) between the upper and lower rollers of the PBA machine. Adjust the position of the upper roller (on the x-axis) to clamp the aluminum channel. Enter the final workpiece arc parameters into the CNC, start the machine, and you’ll achieve a workpiece with satisfactory precision.

Note: Sometimes, springback of the metal can cause the radius to not meet the required specifications on some other machine brands. The PBA machine uses a laser radius measurement and correction device to automatically adjust the bending parameters, achieving precise bending.