uPVC is an ideal material for window profiles due to its lightweight, durability, thermal insulation, and soundproofing properties.

Imagine you are in the kitchen preparing a delicious dessert. You need to knead the dough into a specific shape, then bake it in the oven, and finally achieve a perfectly curved loaf of bread. This process is remarkably similar to how we use hot air guns in a CNC aluminum profile bending machine to heat uPVC window profiles, creating beautiful curved windows.

Preparation

Before making the dessert, you need to select the right dough. Similarly, before manufacturing curved windows, we need to choose the appropriate uPVC window profiles. uPVC material is like a tough dough—hard and durable, but not easily bent at room temperature. To make the uPVC profiles soft and pliable, we need to “preheat” them.

Preheating

In the kitchen, the oven heats the dough, making it soft and easy to shape. In our CNC aluminum profile bending machine, three hot air guns act as the “oven.” They blow hot air evenly to heat the uPVC profiles, gradually raising their temperature and making the material soft and elastic.

You can imagine the hot air guns as a meticulous baker, gently warming the dough with their hands, preparing it for the next step of shaping.

Shaping

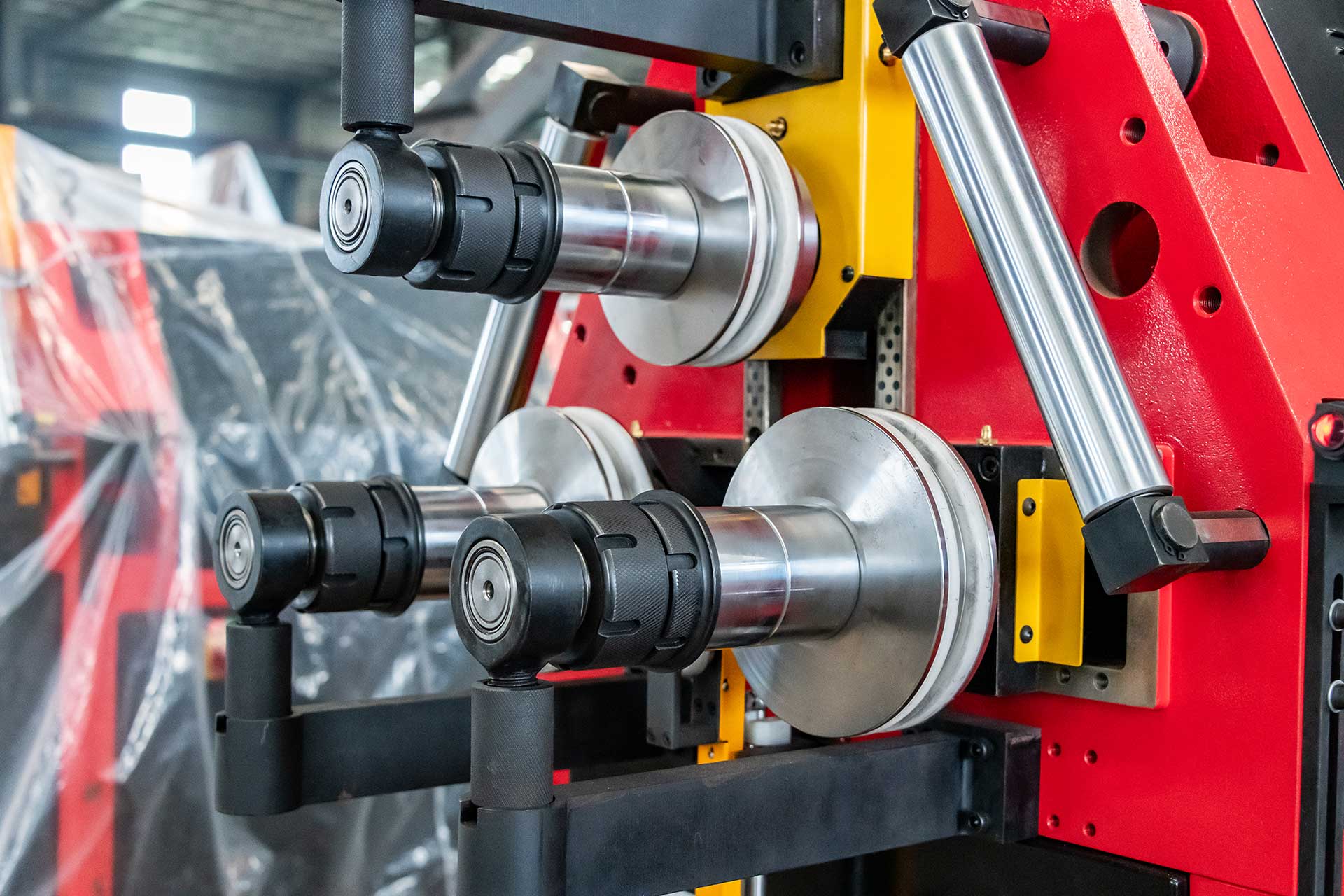

When the dough becomes soft in the oven, the baker uses their hands or molds to shape it into the desired form. In our PBA CNC aluminum profile bending machine, the roll bending machine is like a master sculptor. Through precise mechanical movements, it slowly bends the heated uPVC profiles into the predetermined curve.

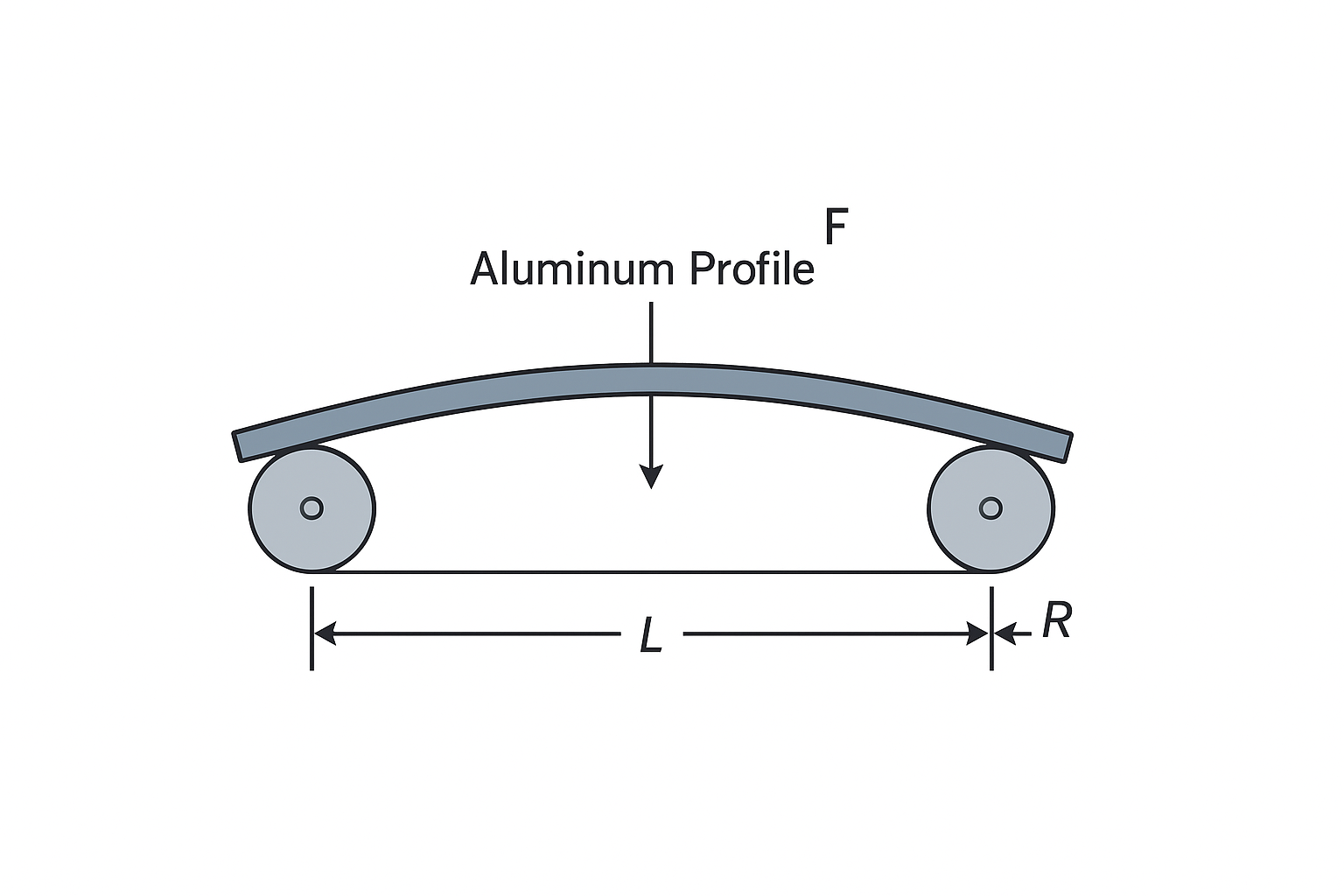

The principle of roll bending is similar to using a rolling pin to flatten or curve dough. The roll bending machine applies even pressure to the heated uPVC profiles through the coordinated action of multiple rollers, gradually shaping them into the desired form. These rollers act like the baker’s hands, precisely controlling every movement to ensure the profiles do not wrinkle, crack, or deform during bending.

This process requires extremely high precision, much like crafting a perfect curved loaf of bread. A slight mistake could ruin the shape. Therefore, every movement of the roll bending machine is carefully calculated to ensure the final curved windows are both aesthetically pleasing and meet design requirements. The machine’s fully servo-driven system and advanced CNC control system allow even complex curves (such as C-shapes, U-shapes, S-shapes, parabolas, etc.) to be bent with precision, ensuring each workpiece meets strict tolerances and perfection.

The PBA CNC aluminum profile bending machine uses fully servo-driven technology with a repeat positioning accuracy of ≤0.01mm. This means even the most complex contours can be bent consistently and accurately, ensuring every workpiece is flawless. It’s like a skilled baker who can shape every piece of dough into an identical form.

Through the skillful hands of the roll bending machine, the heated uPVC profiles are given new life, transformed into beautiful curved windows that add unique charm to buildings.

Cooling and Setting

After the bread is taken out of the oven, it needs time to cool and set to maintain its perfect shape. Similarly, after being shaped by the roll bending machine, the uPVC profiles need to cool to ensure the curves remain permanent.

During this process, the uPVC profiles gradually return to room temperature, the material hardens again, and the shape of the curved windows is fixed. Just like cooled bread, the curved windows are not only beautiful but also strong and durable.

The Final Product

In the end, after heating with hot air guns, shaping with the roll bending machine, and cooling, we achieve a beautiful curved window. It is like a piece of art, not only enhancing the aesthetics of the building but also showcasing the exquisite craftsmanship of modern manufacturing technology.

Conclusion

By softening uPVC profiles through heating and combining them with the high precision and automation of CNC aluminum profile bending machines, we can effortlessly create beautiful curved windows. The entire process is like preparing a delicate dessert in the kitchen—every step requires careful preparation and meticulous execution. In the end, we not only obtain a practical product but also enjoy the fun and sense of accomplishment during the manufacturing process.

Whether making bread or crafting windows, careful preparation, the right tools, and patient waiting are the keys to success. We hope this article gives you a more intuitive understanding of how CNC aluminum profile bending machines work and fills you with respect and curiosity for modern manufacturing technology.

Further reading

Why is Heating Necessary?

Heating is required when bending PVC window profiles because polyvinyl chloride (PVC) is hard and brittle at room temperature. Direct mechanical bending may cause cracking, deformation, or stress concentration, affecting structural integrity and aesthetics. Heating activates the molecular chains, softening the material and significantly improving flexibility. This allows the profile to bend into the required shape under external force without breaking or damage.

Key Considerations

When bending heated PVC profiles, the material’s physical state changes, reducing internal stress and preventing cracking or deformation. This allows for complex bending operations without damage. Once the bending is complete, the material cools and solidifies, maintaining the new shape.

Temperature control is crucial during heating. The typical heating range for PVC profiles is 120°C to 150°C, depending on the PVC formulation, profile thickness, and bend radius. If the temperature is too low, the PVC will not soften sufficiently and may still crack during bending. If the temperature is too high, the PVC may degrade, leading to reduced performance or even melting. Therefore, heating should be performed using heat guns, ovens, or heating belts to ensure even heat distribution and prevent overheating or insufficient heating.

Custom-Built Solution

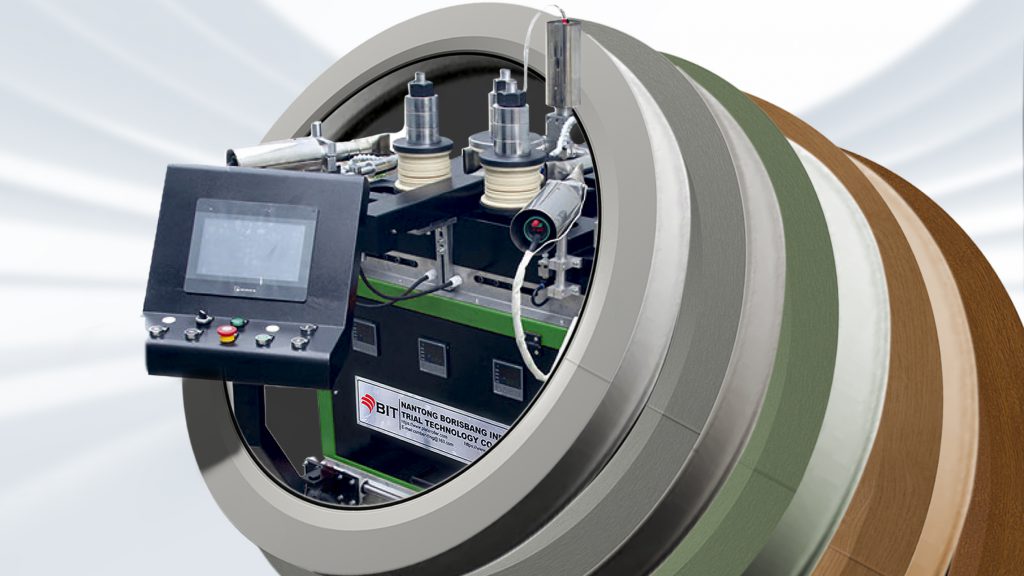

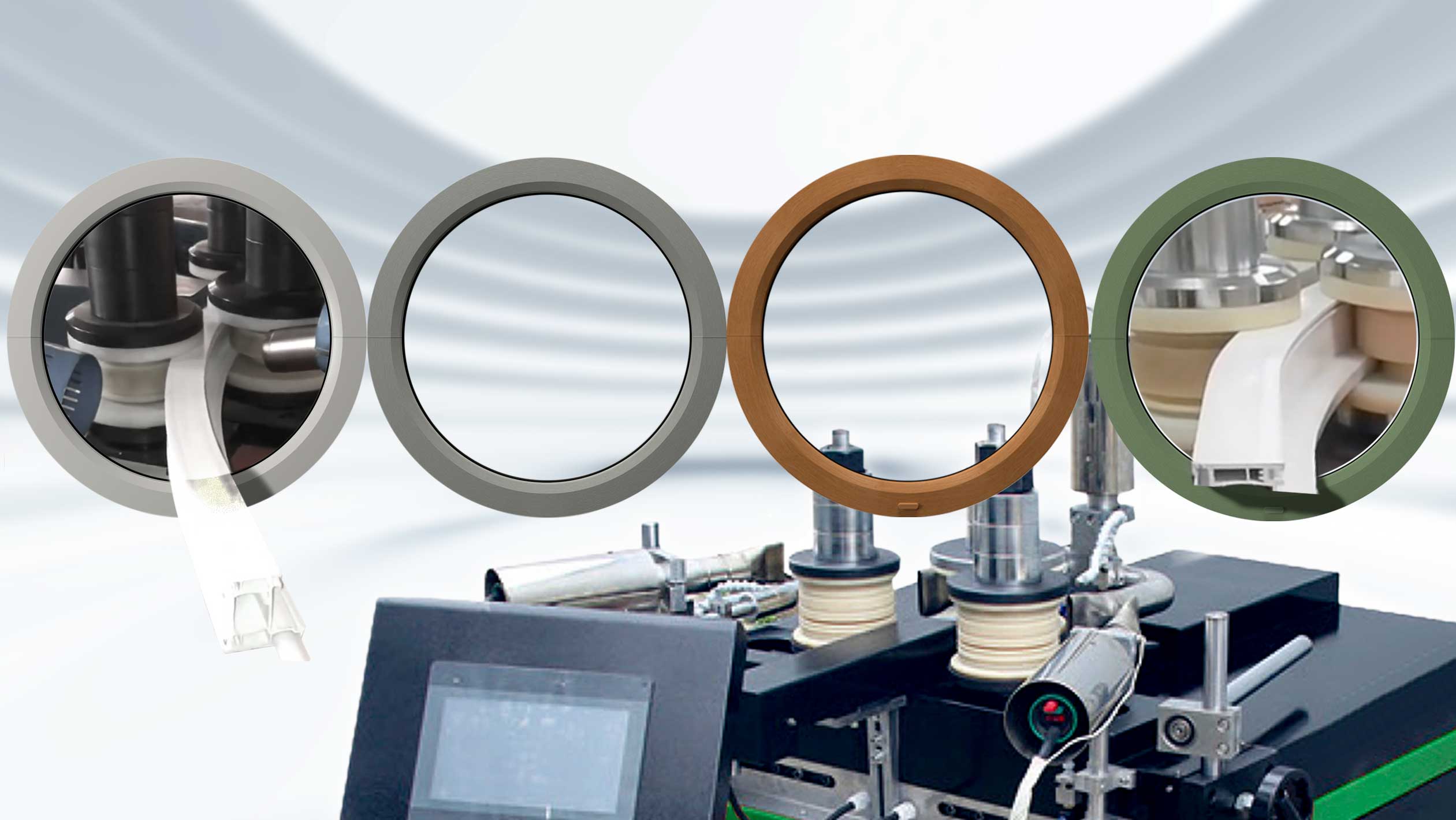

The images below show our custom-built machine for PVC window profiles and a curved PVC window profile sent by a U.S. customer (February 26, 2025).

Our customized PBA-500+ aluminum profile bending machine uses three heat guns for real-time heating of PVC window profiles. Combined with high-precision roller bending from the PBA aluminum profile bending machine, it ensures consistent accuracy in curved window profiles.

Hello,

We are interested in a uPVC and aluminium bending machine.

Delivery to Romania.

Please send price for machine, options, and rolls.

We need a precise and flexible machine.

Thank You

Thank you for your inquiry. I have already replied to your email.

Hello,

We are interested in learning more about your PVC profile bending machine. Do you have an estimate on how much it would cost?

Thank you,

Raiyan Faruqui

Product Development Engineer

Thank you for your inquiry. I have already replied to your email.