Stretch Forming Aluminum Extrusions

Solutions for Aluminum Extrusions Stretch Bending in Aerospace, Automotive, High-Speed Rail, and Construction

What is Stretch Forming?

Stretch forming/bending is a plastic forming technology in the field of materials science and engineering, and is also one of the most common forming processes for aluminum extrusions. By applying axial tensile force during bending, the process alters the stress state of the workpiece, minimizes springback, and achieves highly accurate contour shapes. This technique is widely used in aerospace manufacturing—such as aircraft frames, fuselage skin panels, and missile structures—and in civilian applications including aluminum extrusion components like automotive window frames and architectural profile systems.

The stretch forming process consists of three stages: pre-stretching to material yield, maintaining tensile force during bending, and post-stretching to ensure dimensional accuracy. Stretch forming process classifications include hot and cold stretch forming, forming direction types, and equipment categories.

Stretch Forming Process Principle

In the Stretch Forming process, the workpiece is subjected to axial tensile force while being bent, generating tensile stress along its longitudinal direction. This tensile stress, combined with the bending moment, redistributes the stress within the workpiece cross-section, mitigating stress concentration and springback commonly observed in conventional bending.

When the axial tensile force exceeds the material’s yield strength, the outer layer of the workpiece experiences tensile stress while the inner layer is under compressive stress. This stress distribution effectively counteracts elastic springback, allowing the formed profile to maintain precise curvature while preserving its cross-sectional shape.

Moreover, by carefully controlling the magnitude and timing of the tensile force, material plastic flow can be optimized, minimizing local wrinkling, cracking, and surface defects, while ensuring bending radius, contour, and dimensional accuracy. The process can be divided into three stages: pre-stretching to the material’s yield, maintaining tensile force to complete bending, and supplementary stretching to ensure forming precision. The method can be further optimized by combining hot or cold stretching, different bending directions, and varying equipment types.

This principle is applicable not only to aluminum extrusions but also to steel structural profiles, composite material profiles, and other materials with sufficient plasticity.

Application

- Aerospace Industry: Used in the manufacturing of primary load-bearing components such as aircraft fuselage frames, longerons, and wing spars. These parts require a combination of high strength and lightweight design to ensure flight performance and safety. Stretch forming technology enables precise control of curvature and cross-sectional dimensions of aluminum extrusions, meeting strict engineering requirements.

- Space Industry: Applicable to large-curvature components such as rocket fuel tank transition rings, missile body frameworks, and other aerospace structures. These parts often feature complex surfaces and high strength requirements. Stretch forming aluminum extrusions effectively reduces springback, ensures dimensional accuracy, and maintains structural integrity.

- High-Speed Rail: Used for car body components such as curved beams, side columns, and door posts. These parts require large dimensions, high precision, and complex curvature. Stretch forming of aluminum extrusions ensures accurate contours, reduces springback, and maintains structural integrity.

- Automotive Manufacturing: Widely used for stretch forming aluminum extrusions in car body structural components, doors, window rails, roof racks, and other parts. Stretch forming supports vehicle lightweighting and high-precision assembly, while enhancing overall structural strength and safety.

- Civil Construction: Applied to architectural facades, aluminum window frames, roof steel structures, and other building profiles. Stretch forming of aluminum extrusions ensures accurate curvature, smooth surfaces, and structural stability for large-span or irregular profiles, providing reliable support for modern architectural design and functionality.

Stretch Forming Process

The stretch forming process consists of three key stages—pre-stretching, bend forming, and secondary stretching—each carefully controlled to ensure uniform deformation, minimize springback, and achieve precise final profile geometry.

Pre-Stretching Stage

During the pre-stretching stage, an axial tensile force exceeding the material’s yield strength is applied to the profile, generating uniform plastic deformation and eliminating initial bending or twisting caused by rolling, extrusion, or transportation. This process induces work hardening, increasing the material’s yield strength and ensuring stability and strength during subsequent bending.

The key function of pre-stretching is to place the entire profile cross-section under tensile stress, effectively providing a “background tension” that shifts the neutral axis outward during bending. The pre-stretching force is typically controlled to produce 1%–3% permanent plastic elongation, and should fall between the material’s yield strength and tensile strength. Specific values are determined based on the material grade, cross-sectional shape, and size, using experimental data or empirical formulas. The process must be carried out smoothly and evenly along the full length of the profile to prevent localized necking or fracture, ensuring high forming accuracy and maintaining the integrity of the cross-section.

Bend Forming Stage

During the bending stage, the profile is formed under a constant tensile force, with careful control of stress distribution throughout the process. While maintaining the pre-stretch force (or slightly higher), the bending tool (such as a stretching arm) gradually shapes the profile along the die surface. Due to the pre-stretch, compressive stress on the inner side of the profile is significantly reduced, and in some cases, the entire cross-section experiences tensile stress. This effectively minimizes wrinkling on the inner side and cracking on the outer side, demonstrating the coupled effect of stretching and bending. The constant tensile force acts like a “straightening” force, ensuring the material conforms closely to the die and flows evenly over the mold surface.

High-precision bending dies are typically pre-compensated rather than matching the theoretical part profile. Compensation is calculated based on material properties, cross-sectional shape, and process parameters to counteract springback after demolding. Bending speed must be carefully controlled: excessive speed can cause dynamic effects that disrupt material flow and stress distribution, while too slow a speed reduces efficiency. Proper speed control ensures uniform plastic deformation along the profile length, accurate curvature, and optimal balance between forming quality and production efficiency.

Secondary Stretching Stage

After bending is completed, additional tensile force is applied to compensate for the material’s elastic springback, ensuring the final contour accuracy of the part. During bending, internal elastic stresses tend to return the material to its original shape. The secondary stretching applies extra force to key areas, inducing slight plastic deformation to “lock in” the bent shape. This step is critical to ensure the part profile closely matches the die surface, directly affecting the final product quality.

The secondary stretching force is usually higher than the pre-stretching force but must remain below the material’s tensile strength to ensure safety and prevent fracture. By applying a controlled amount of additional plastic deformation (e.g., 0.5%–1%), the elastic springback can be precisely counteracted, allowing the part to achieve the designed curvature and dimensional accuracy across the entire or key regions.

Process Parameters and Their Effects

The process parameters in stretch forming are critical for ensuring precise bending, dimensional accuracy, and high-quality profiles. These parameters are determined by material properties, operational settings, and friction or contact conditions, which together govern the material’s behavior throughout pre-stretching, bending, and secondary stretching stages.

Material Properties: Material characteristics form the theoretical basis for setting process parameters. Different materials exhibit distinct bending behaviors, with yield strength directly determining the required pre-stretch and secondary stretching forces. Materials with higher yield strength require greater tensile forces. Elastic modulus reflects the material’s resistance to elastic deformation; materials with a high elastic modulus show more pronounced springback, requiring precise die compensation and higher secondary stretching force. The strain-hardening exponent indicates how quickly the material strengthens during plastic deformation. Materials with high hardening rates promote uniform deformation but also require higher forming forces and carry an increased risk of cracking. Anisotropy, particularly in rolled or extruded profiles, can lead to warping or twisting during bending if the directional properties are significant.

Process Parameters: These are the controllable operational variables that directly influence the forming process. The pre-stretch force is typically set to induce 1%–3% uniform plastic elongation. Insufficient force may result in wrinkling on the inner side, while excessive force can consume the material’s plasticity and cause cracking on the outer edge during bending. Secondary stretching force is usually higher than pre-stretch force, designed to produce an additional 0.5%–1.5% plastic deformation to precisely counteract elastic springback. Forming speed affects material flow and stress distribution; excessive speed may introduce dynamic effects, while too slow a speed reduces efficiency. Smooth, moderate-speed operation is recommended.

Calculate the stretch forming force for your aluminum profile! Estimate the flat development length, bending radius, and required tooling with our online calculator designed specifically for aluminum profile stretch forming: Aluminum Profile Stretch Forming Calculator

Friction and Contact Conditions: The interface between the die and the workpiece is critical for accurate force and shape transfer. Proper lubrication reduces friction, ensuring uniform tensile force distribution, smooth material flow, and preventing surface scratches or pulling defects. The die surface’s finish, hardness, and geometric accuracy directly affect the profile surface quality; rough surfaces increase friction and may leave impressions. Clamping design must prevent slippage or loosening under high tensile forces while avoiding damage to the profile ends. Reliable clamping is essential for successfully performing both pre-stretching and secondary stretching stages.

Technical Advantages

The stretch forming process achieves high-precision forming of complex components through the precise coupling of stretching and bending. Its core advantages are highlighted in the following three aspects:

The process is particularly suitable for manufacturing components with large bending radii (R/t ≥ 5), variable curvature, and complex three-dimensional structures. Continuous axial tensile force effectively maintains the shape of thin-walled, non-standard cross-sections, preventing instability and distortion during bending.

Compared with conventional free bending or roll bending, stretch forming actively controls stress through the “pre-stretching – forming – secondary stretching” sequence, fundamentally suppressing material springback. Forming accuracy, measured by die-surface conformity, is typically 40%–60% higher than traditional methods, ensuring extremely high profile fidelity and significantly reducing the need for subsequent correction.

Stretch forming is an ideal solution for high-performance materials such as aluminum alloy extrusions and titanium alloys, which exhibit strong springback tendencies that are difficult to control with conventional methods. The process’s “stretching-instead-of-compressing” mechanical principle effectively mitigates springback, ensuring precise and stable final shapes.

Whether designing aerospace components, architectural profiles, or high-precision automotive parts, the stretch forming solutions deliver unmatched precision, efficiency, and material performance. By leveraging advanced stress control, pre-stretching, and die compensation techniques, the stretch forming guarantees minimal springback and exceptionally accurate dimensional fidelity.

Want to go deeper into how stretch forming works in real manufacturing?

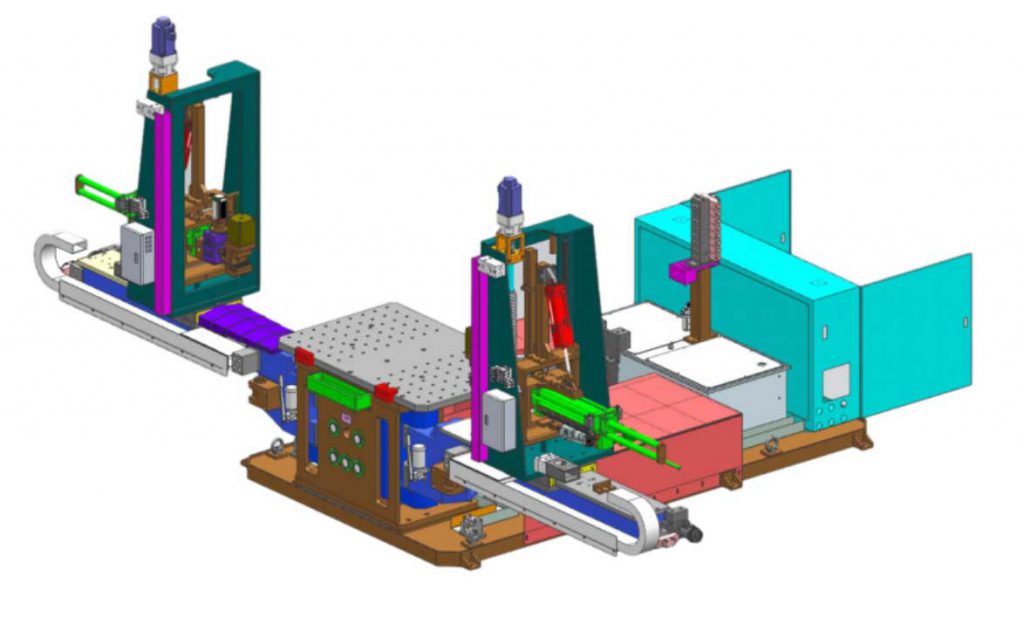

In the following section, you will find a detailed explanation of the aluminum profile stretch forming workflow, including equipment setup, clamping principles, and force control. It also introduces the structural differences between 2D and 3D stretch forming machines, and how each design improves precision for complex profiles.

Read more in: Aluminum Profile Stretch Forming Process of Aluminum Extrusions.