Roll bending of aluminum profiles is a forming method that bends the profile by means of rotating rollers.

Section 2: Roll Bending Process

Roll bending is a plastic forming process in which a set of rotating rollers gradually bends an aluminum profile into a specified shape. It is widely used in manufacturing circular structures, arc-shaped components, and even multi-radius or three-dimensional spatial parts.

Table of Contents

This article series is divided into three sections, each focusing on a different aluminum profile bending and forming method. You may navigate to any process below:

Aluminum Profile Bending & Forming Processes

Stretch Bending Process

https://www.aluminumbendingmachine.com/stretch-bending-forming-process-of-aluminum-profiles;

Roll Bending (Roll Forming) Process

https://www.aluminumbendingmachine.com/aluminum-profile-bending-forming-2-roll-bending;

Press Bending Process

(Coming soon)

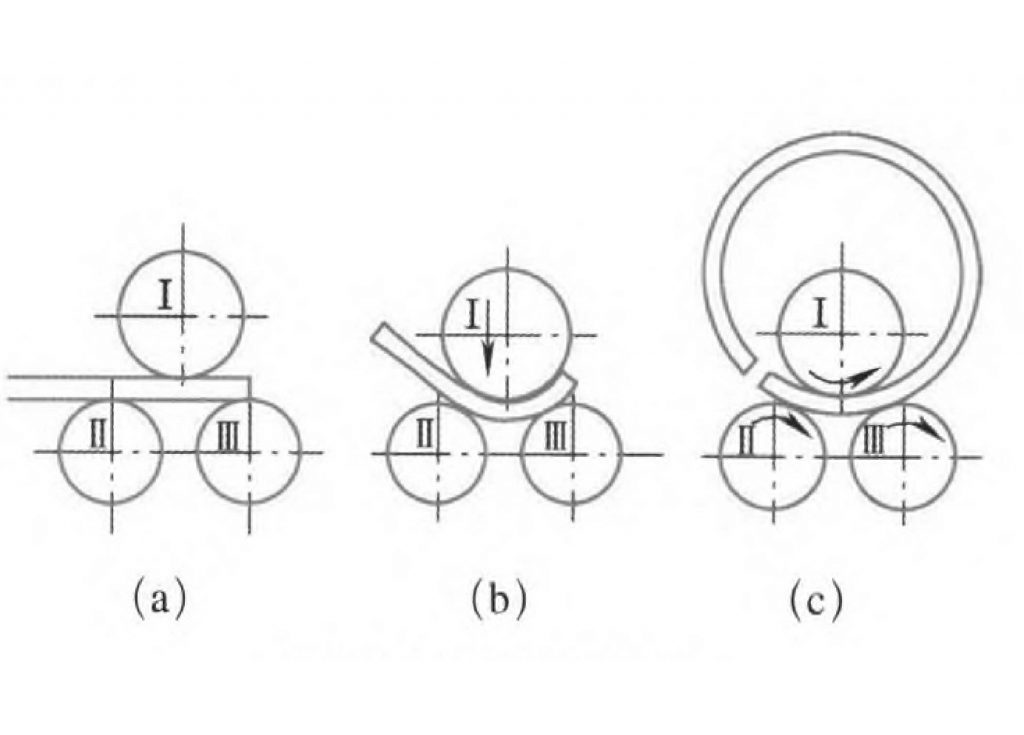

Working Principle of Roll Bending

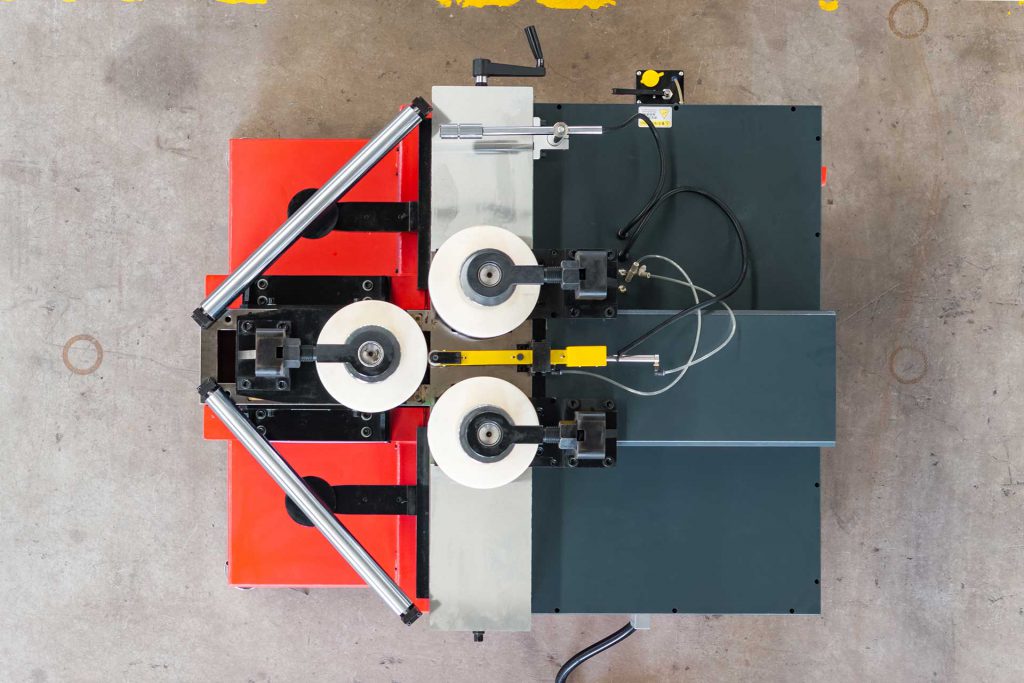

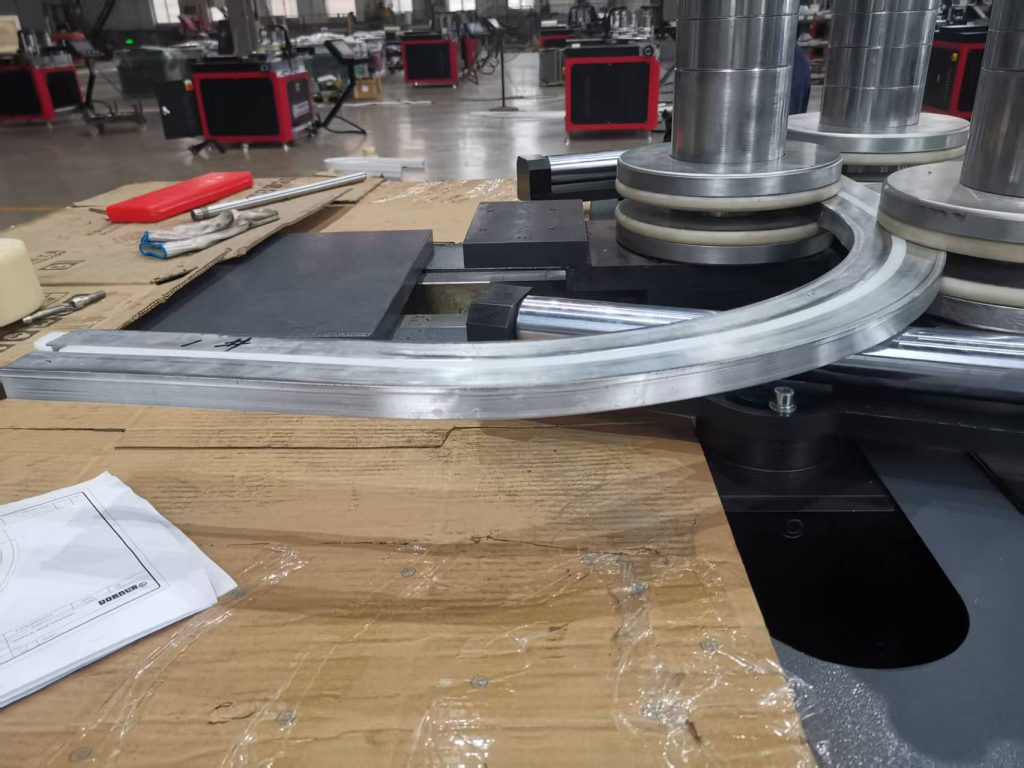

Aluminum profile bending machines are generally divided into vertical and horizontal types. The main equipment includes three-roll aluminum profile bending machines, four-roll aluminum profile roll bending machines, and multi-roll aluminum profile rolling machines. Vertical aluminum profile roll benders provide convenient loading and operation, while horizontal machines are preferable for long and large workpieces.

In CNC aluminum profile rolling machines, the position of each axis is precisely controlled by servo motors (with hydraulic systems regulated by servo proportional valves). The axes are driven in linkage and controlled by a programmable logic controller (CNC). While the roller shafts of the machine perform the bending operation, encoders simultaneously monitor the arc length of the workpiece in real time and feed the data back to the system. According to the preset program, the equipment performs multiple reciprocating bends or multi-radius bending trajectories.

Characteristics of the Roll Bending Process

Roll bending of aluminum profiles can be divided into two types: 2D roll bending and 3D roll bending. During processing, the curvature is controlled by adjusting the distance or tilt angle between the rollers, while the rotational friction of the rollers drives the material forward and forms it.

Aluminum profile bending machines are mostly used to produce single-radius components. They offer short mold-making cycles, low tooling costs, and simple operation. For multi-radius parts, CNC aluminum profile bending machines can achieve multi-curve forming requirements, but due to variations in material hardness and differing deformation levels in each arc segment, springback becomes inconsistent. As a result, workpiece consistency can be poor, requiring manual reshaping afterward. Roll bending is suitable for mass production of single-radius parts or small-batch production of multi-radius components.

Key Technologies in Roll Bending

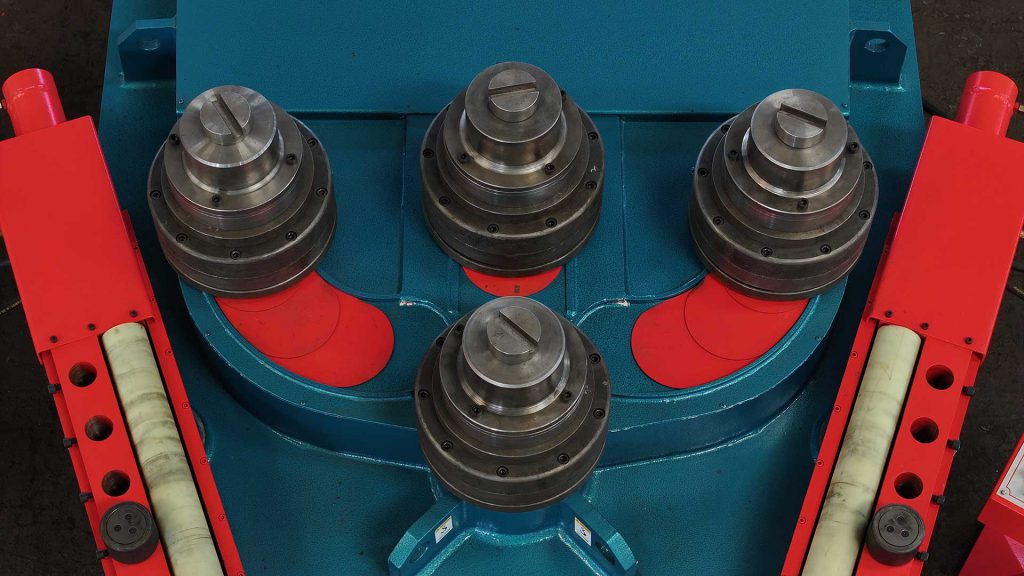

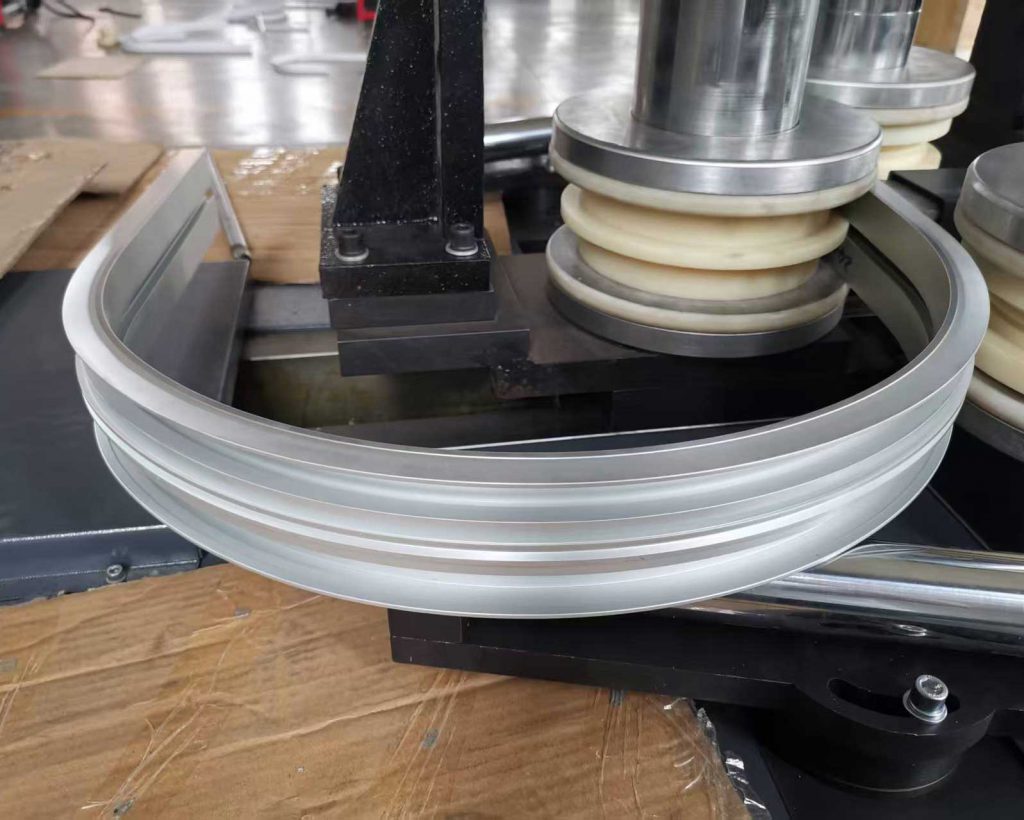

The difficulty of roll bending depends on the cross-section geometry of the material. The design of the roller dies is critical to forming quality. Roller molds are typically made of quenched and tempered 45# steel or tool steel, machined on a lathe and then heat-treated and chrome-plated to achieve the required hardness and surface finish. For irregular or asymmetrical profiles, the rollers can easily scratch the aluminum surface. Nylon inserts between the steel roller and the aluminum profile can be used to maintain mold strength while preventing direct contact and avoiding surface damage.

During roll bending, it is also necessary to consider the shift of the neutral axis, which may cause material thinning or thickening. Multi-roller straightening is applied to eliminate defects such as straight-end deformation.

Calculation of Roll Bending Capacity

To determine whether an aluminum profile bending machine can meet the process requirements of a bending task, the following conditions must be satisfied:

- The roller shaft length must be sufficient for the width of the material.

- The machine’s minimum achievable bending radius must be smaller than or equal to the minimum radius required by the workpiece.

- The available forming force of the machine must exceed the roll bending force required by the material.

Interestingly, we even created a little calculator to help you check all of this instantly — feel free to try the Roll Bending Force Calculator before diving into the theory below.

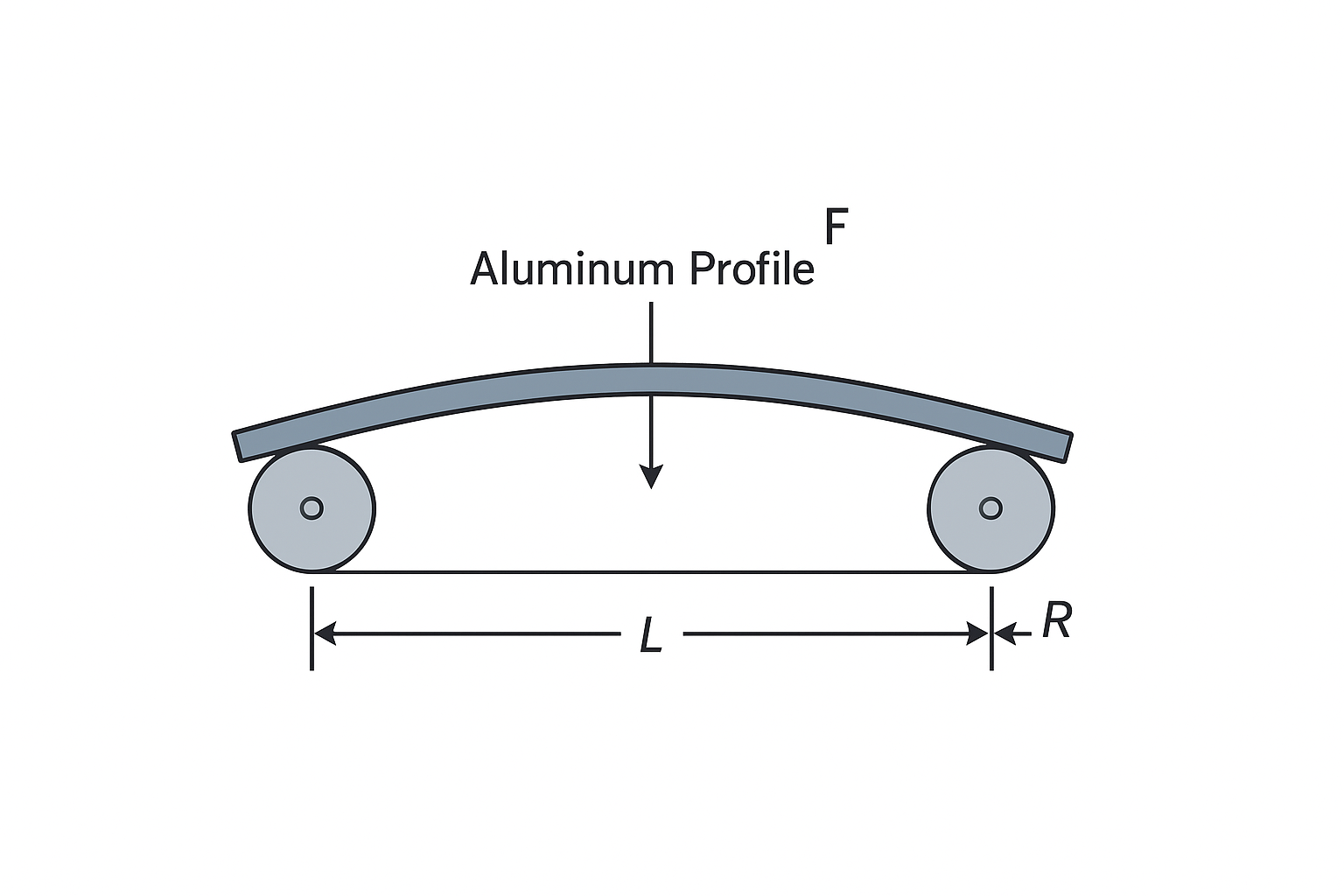

The calculation of roll-bending forming force serves as the theoretical basis for verifying a roll bending machine’s capability during the drawing and process evaluation stage. The forming force calculation for roll-bent workpieces is as follows:

Roll Bending Forming Force

Formula:

Proll= 48*E*F*I/L 3

Where:

- Proll — Bending force applied during roll bending of the profile (N)

- F — Deflection, i.e., chord height of material deformation (cm)

- E — Elastic modulus (105 N/mm²)

- I — Moment of inertia of the profile cross-section (cm⁴)

- L — Span between roller support points (cm)

This page explains the roll-bending process used to form curved aluminum profiles.

For machines designed for this bending method, visit the Aluminum Bending Machine homepage