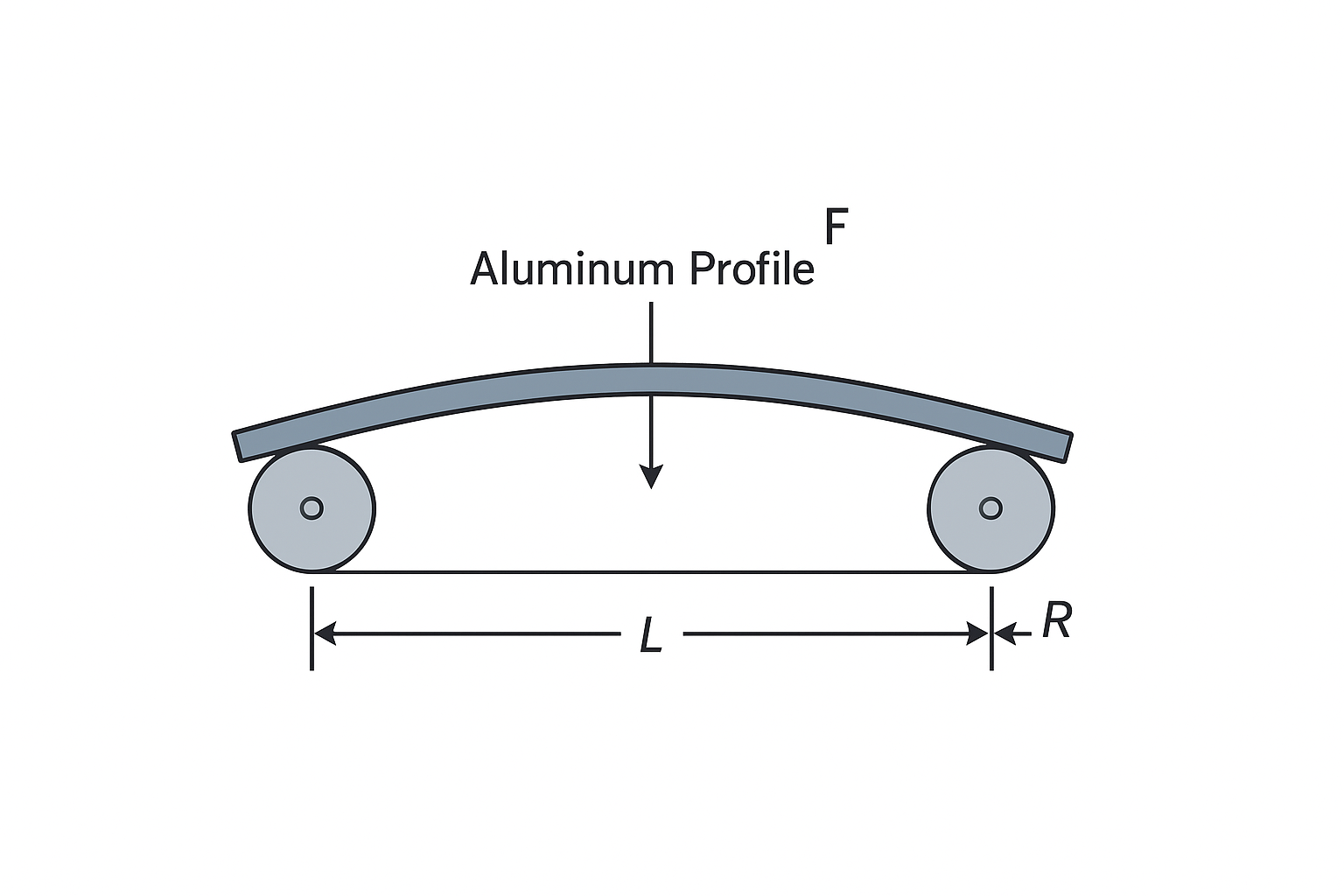

During the stretch forming of end beam components, common defects include web buckling and sidewall cross-sectional distortion. The severity of cross-sectional distortion increases with the amount of stretch. For this component, a reasonable stretch amount is 8% of the profile length, and the corresponding mold surface correction should be set to 1.3 times the springback.

In recent years, the rapid development of China’s high-speed rail and urban rail transit systems has directly driven the upgrading of related industrial chains. One of the most significantly benefited sectors is the aluminum processing industry. Rail vehicle bodies primarily use aluminum profiles and sheets as core materials, demanding high strength, dimensional stability, and advanced manufacturing equipment. Due to the substantial equipment investment, high product added value, and technical complexity, this sector has become a key focus of the aluminum processing industry and represents the most profitable market segment in the field of aluminum stretch forming.

Application of Stretch Forming in Rail Vehicle Bodies

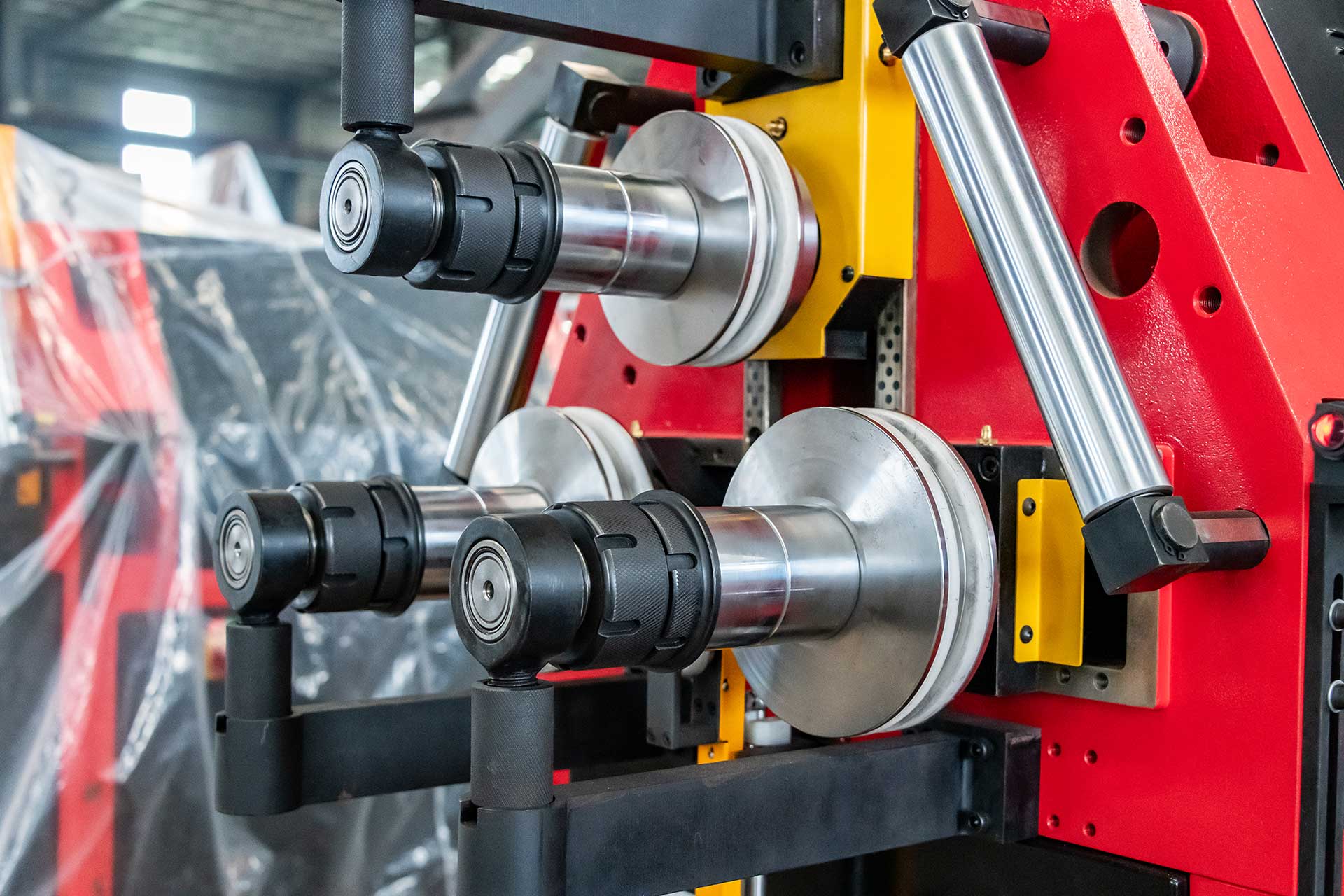

The structures of aluminum rail vehicle bodies are not only large in size but must also meet strict requirements for structural strength, aerodynamic performance, and aesthetics. Consequently, many critical aluminum components are used in a bent state, including bent beams, side columns, and door post pillars. During forming, aluminum stretch forming technology applies tangential tensile forces while bending, improving the stress distribution across the cross-section and reducing springback. This results in significantly enhanced contour accuracy, meeting the high-precision manufacturing requirements of rail vehicle bodies. For complex aluminum profiles with multiple curvature variations, CNC roll bending is typically used to achieve flexible multi-radius forming.

Advantages of CNC Stretch and Roll Bending Technologies

Traditional aluminum stretch bending machines and hydraulic bending equipment have limitations in practice: they provide insufficient control over stress and cross-sectional deformation, making components prone to wrinkling, cross-sectional distortion, and contour errors. They also rely heavily on operator experience, leading to low efficiency and inconsistent precision. In contrast, CNC aluminum stretch bending machines and variable-curvature roll bending equipment, equipped with full numerical control and core algorithms, can precisely control material deformation, minimize springback effects, and enable highly stable, consistent, and efficient production. These technologies significantly improve surface quality and dimensional accuracy while reducing dependence on skilled operators, making them the mainstream choice for aluminum profile bending in rail vehicle manufacturing.

In one study, an aluminum alloy end beam of a high-speed train body was used as a test subject. Numerical simulations were conducted to analyze the influence of process parameters on cross-sectional deformation and contour accuracy, and the aluminum stretch forming process was optimized, providing reliable guidance for actual production.

Factors Affecting Contour Accuracy and Optimization Methods

Experiments show that the amount of aluminum stretch during forming is the key factor affecting springback and contour accuracy. Within a reasonable range, increasing the stretch reduces springback, improving contour precision. However, excessive stretching can lead to cross-sectional distortion or even web buckling.

To further improve accuracy, a springback-based mold surface reverse correction method can be employed. This involves applying varying correction factors to different positions of the aluminum mold, so that the formed part’s springback aligns more closely with the theoretical contour. Tests indicate that when the mold correction is set to 1.3 times the springback, contour accuracy improves most significantly, consistently meeting rail vehicle manufacturing requirements.

Summary of Stretch Forming Trials

Stretch forming trials conducted on a PBF-AS 70 CNC aluminum stretch bending machine for the end beam component demonstrated the following:

- Common defects include web buckling and sidewall cross-sectional distortion, particularly in regions with greater bending.

- Cross-sectional distortion increases with stretch, but forming quality remains good when the stretch is less than 8% of the aluminum profile length.

- While increasing stretch reduces springback and improves contour accuracy, it must be balanced against cross-sectional deformation risk. For this component, an 8% stretch combined with a 1.3× mold surface correction proved to be optimal.

This aluminum component has since been successfully applied in the production of aluminum alloy rail vehicle bodies, validating the practical value of the optimized process.

Want to learn more about how stretch forming optimizes aluminum profile bending for rail vehicles?

In the following section, you will find a detailed explanation of the stretch forming process, including the pre-stretch, bending, and supplementary stretching stages. It also covers how axial tensile forces are applied to control cross-sectional stress, reduce springback, and improve contour accuracy.

Read more in: Stretch Forming of Aluminum Profiles