Aluminium Window Bending can be one of the simplest methods for shaping aluminum profiles. However, the process can present challenges, depending on several critical factors:

- Bending Direction: Profiles can bend along the X-X axis (strong axis) or the Y-Y axis (weak axis).

- Window Shape: The desired form of the window significantly influences the process.

- Minimum Bending Radius: Achieving the narrowest bending radius requires careful calculation.

- Powder Coating: Pre-coated profiles risk surface damage during bending.

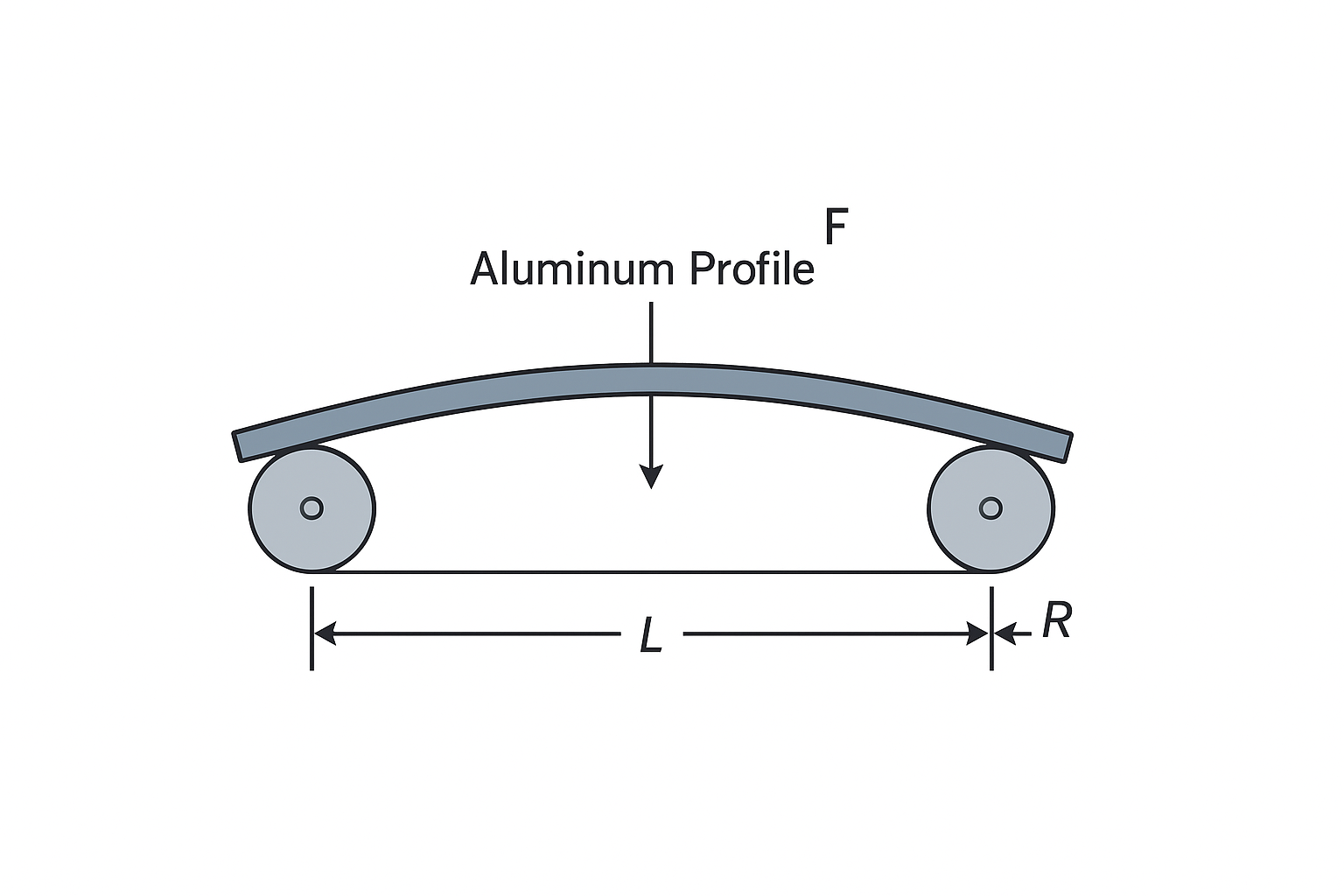

Simple Formula for Minimum Bending Radius

The minimum Aluminium Window Bending radius can be calculated as:

Minimum Bending Radius = Y-axis width × 5

Core Features of Aluminum Window Profile Bending

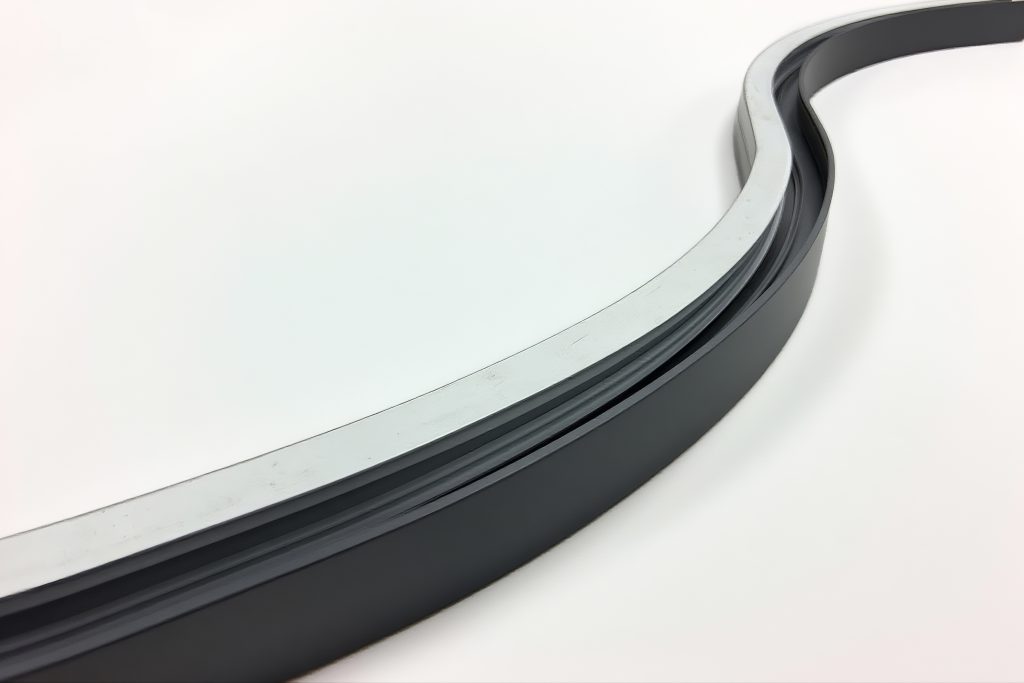

- High-Precision Bending: The process achieves complex curves, circles, or elliptical designs, meeting diverse architectural demands with precise dimensions.

- Material Performance: Profiles are categorized as easy-to-bend or difficult-to-bend based on hardness and plasticity. Easy-to-bend profiles have low hardness and high plasticity, simplifying the process. Difficult-to-bend profiles require more force and energy due to higher hardness and lower plasticity.

- Bending Angles: Angles are divided into small and large bends. Small-angle bends (less than 90 degrees) suit simple designs, while large-angle bends accommodate intricate shapes.

- Bending Radius: Small radii are ideal for compact designs, while large radii work for wide arcs and open layouts.

- Bending Shapes: Straight-line bends fit linear designs, whereas non-linear bends enable curves, arcs, and other complex forms.

- Material Protection: Specialized tools and surface protection prevent damage to coatings, especially on anodized or painted profiles.

- Flexible Adaptability: The process handles profiles of all sizes, from lightweight to heavy-duty, accommodating various radii and design requirements.

- Structural Integrity: Profiles retain their cross-sectional shape during bending, preserving load capacity and structural strength, making them suitable for high-standard applications.

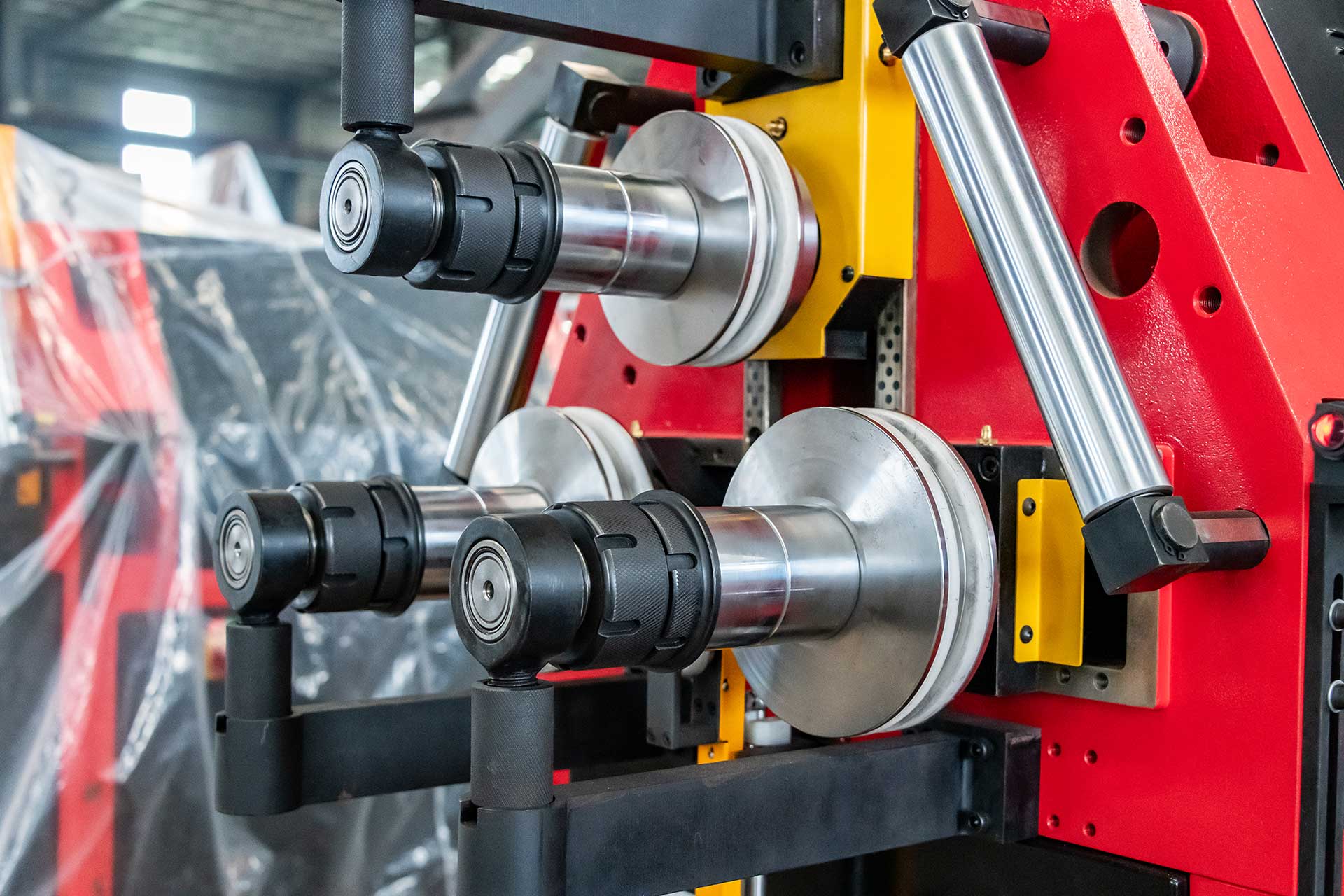

- Efficient Production: Techniques like roll bending and stretch bending boost efficiency, reduce manual effort, and ensure consistent quality.

This process is widely used in curtain walls, windows, and decorative projects, offering versatile and effective solutions.

It is important to note that the above classification is just one common way to categorize the process. In reality, the characteristics of aluminium window bending are often a combination of various aspects, and different features may exist simultaneously. For specific profiles and application requirements, it is necessary to select and optimize process parameters based on the actual situation.