Stretch forming enables aluminum profiles to achieve complex, high-precision curvatures with enhanced structural strength and reduced springback. However, improper forming parameters can lead to defects such as fracture, wrinkling, surface distortion, and dimensional deviation. Understanding how stress states influence deformation and how to control process variables is essential to ensure reliable forming quality and cost-effective production.

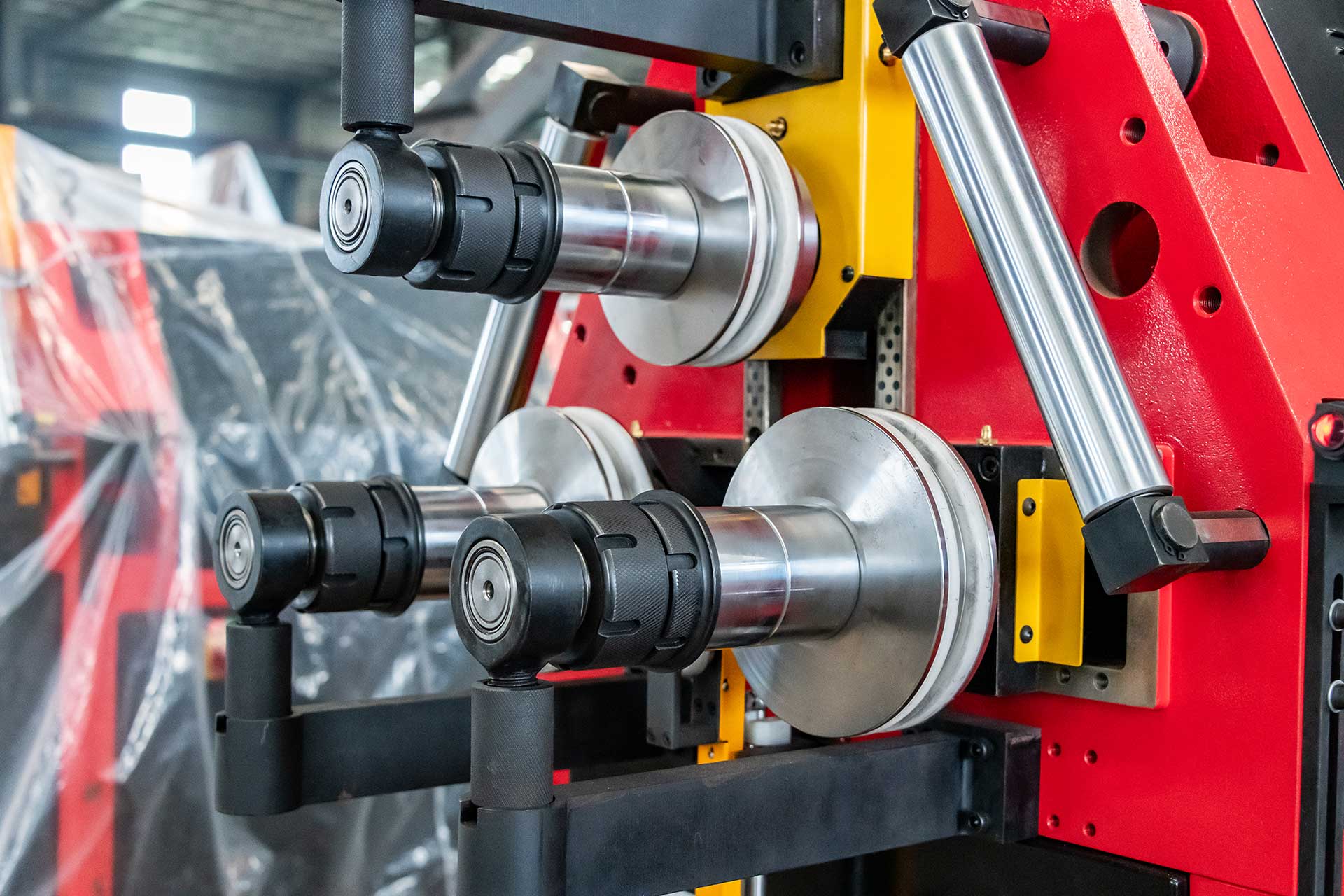

Perhaps first see the full aluminum profile stretch forming process before learning how to solve defects and optimize production.

Key Technologies in Stretch Forming

The curvature design of stretch-formed parts must not exceed the elongation limit of the material. During Stretch Forming, defects such as wall thinning and fracture, wrinkling, and cross-sectional distortion may occur. These issues are closely related to the mechanical properties of the alloy, the cross-sectional geometry, and the applied Stretch Forming process parameters.

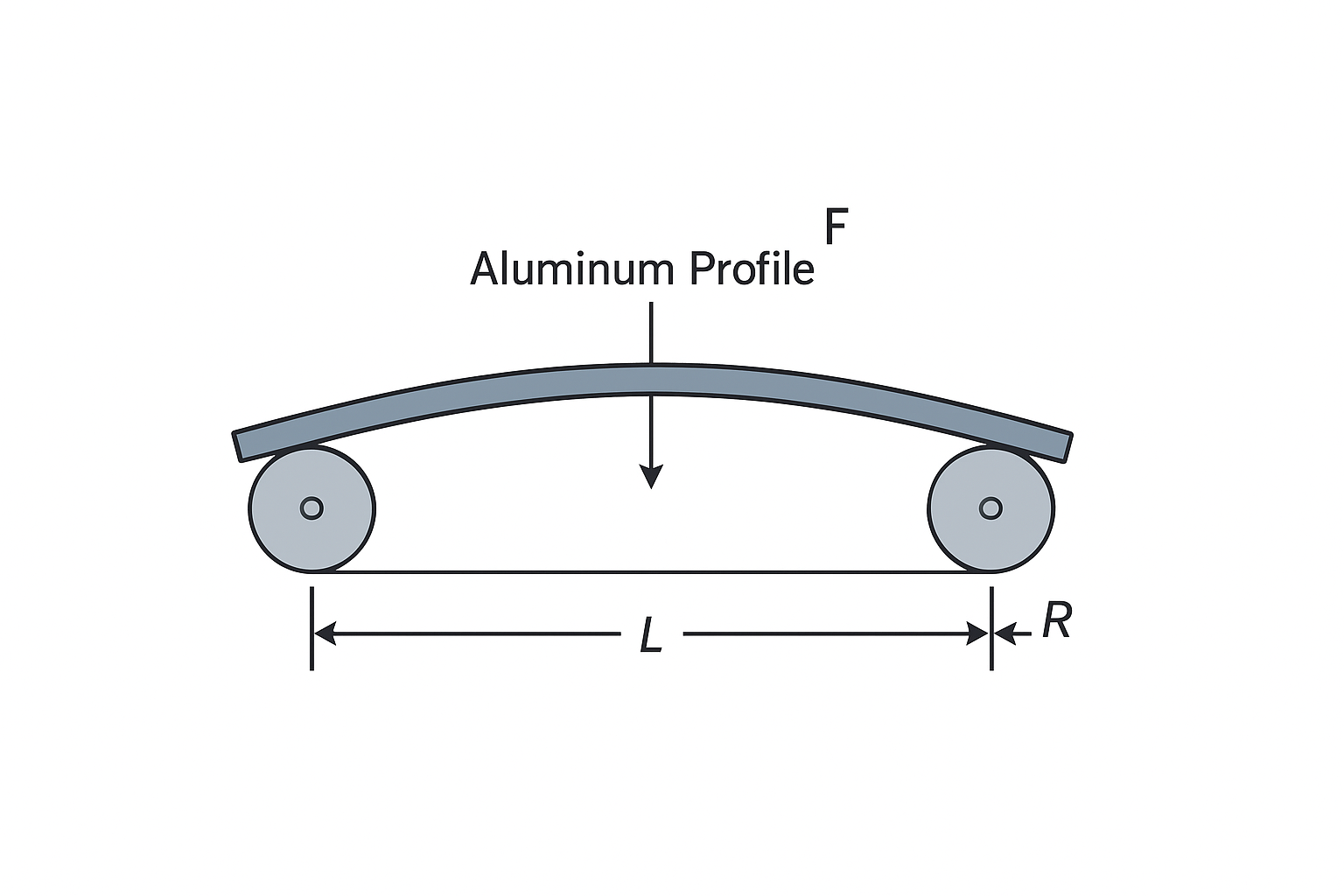

During Stretch Forming, different stress states exist across the deformation zone. Materials outside the neutral layer are subjected to tensile stress, while materials inside the neutral region (in contact with the forming die) experience compressive stress. To prevent wrinkling caused by compressive stress, the applied pre-stretching force must be sufficient to make the material yield in tension. However, higher tensile force intensifies thinning and may cause fracture of the metal outside the neutral layer.

Therefore, determining proper Stretch Forming parameters requires balancing two critical factors: preventing compressive wrinkling in the die-contact region, and avoiding fracture and excessive cross-section deformation caused by overstretching beyond the neutral layer.

Common Problems and Solutions in Aluminum Profile Stretch Forming

Problems:

- Contour deviations: due to die springback, material inconsistencies, radius variation, or uneven cross-section.

- Surface defects: cracks, wrinkles, concaves, and side indentations.

- Twisting after bending: caused by asymmetric cross-sections or stress imbalance.

- Excessive vertical deviation: misalignment of cross-section relative to reference plane.

- Excess material length: extra length required for dies, clamps, and machine clearance.

- Safety hazards: sudden material breakage can damage equipment or injure personnel.

Solutions:

- Adjust die curvature based on calculations and tests to compensate for springback; add cylinders for better die conformance.

- Prevent surface defects by modifying cross-section, adjusting tension, or filling cavities before bending.

- Reduce twisting by adding vertical push cylinders and maintaining pressure after forming.

- Correct vertical deviations by adjusting die curvature and post-processing.

- Optimize material length to reduce waste while ensuring proper forming.

- Implement safety measures: protective shields, standard operating procedures, and operator training; prohibit standing near active stretch forming machine.

Conclusion

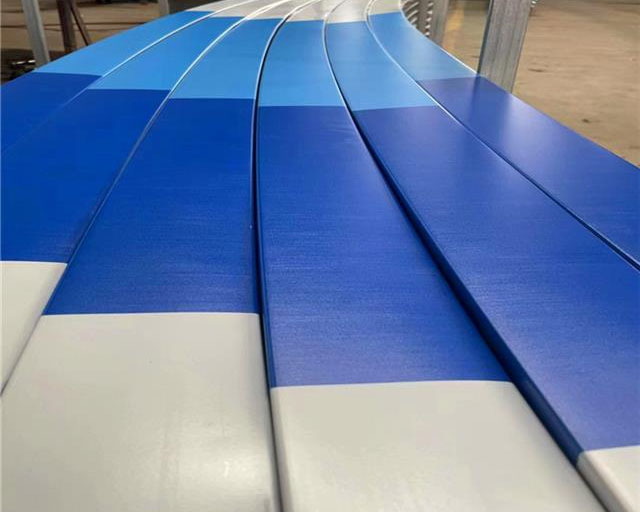

Aluminum alloy profile stretch forming is a key process in modern manufacturing and construction industries. By optimizing bending parameters, improving die design, and strengthening process control, it is possible to enhance forming precision, surface quality, minimize springback, reduce defects, and achieve high-quality, cost-effective production.

Want to quickly estimate the required force, blank length, and bending radius for aluminum profile stretch forming? This page provides a practical calculator tool designed specifically for stretch forming applications. By entering your profile dimensions and material data, you can instantly obtain key forming parameters and process recommendations. Use the calculator to support accurate tooling design, production planning, and process optimization.