-

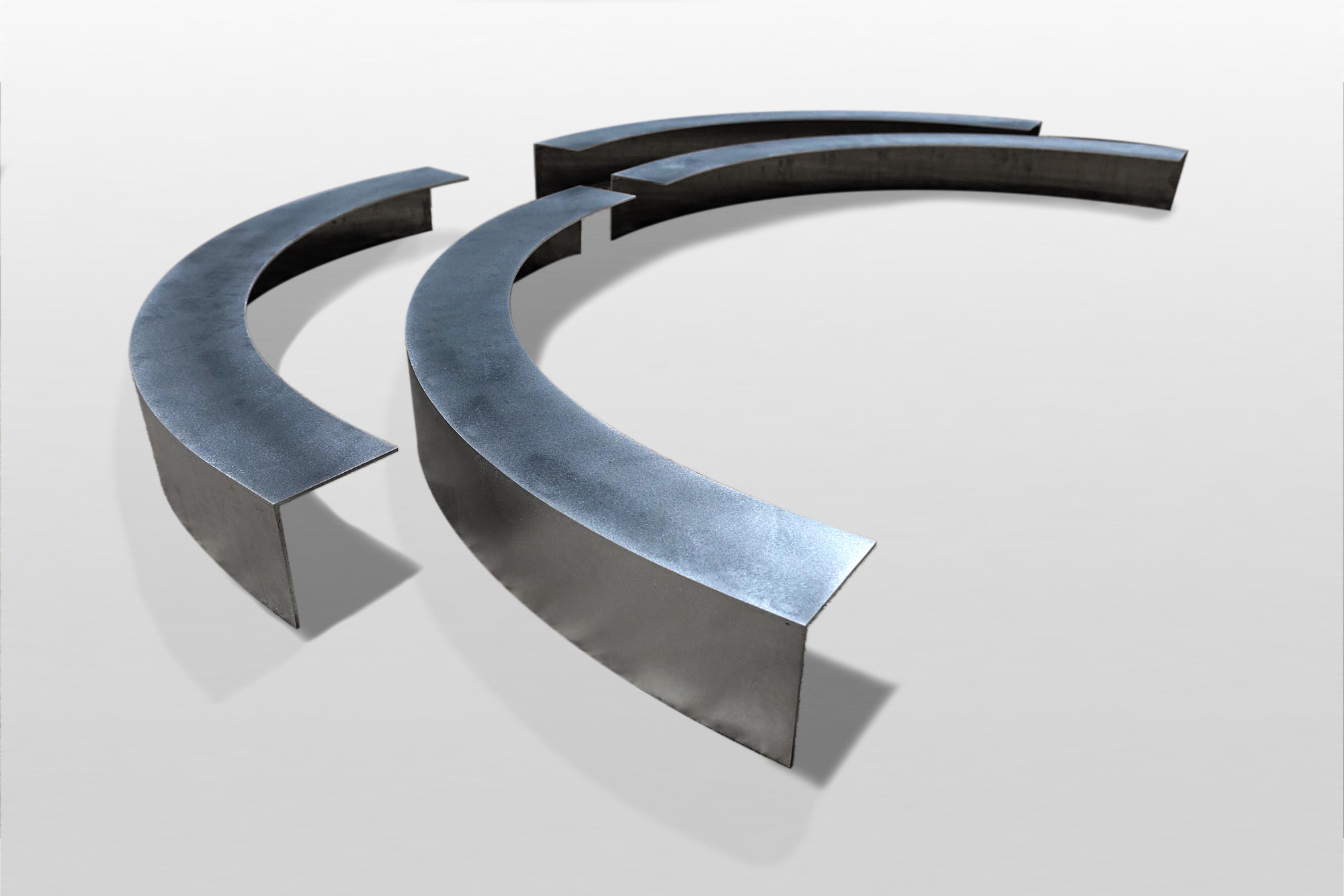

Stretch Forming Process of Rail Vehicle Body End Beams

During the stretch forming of end beam components, common defects include web buckling and sidewall cross-sectional distortion. The severity of cross-sectional distortion increases with the amount of stretch. For this component, a reasonable stretch amount is 8% of the profile length, and the corresponding mold surface correction should be set to 1.3 times the springback.

-

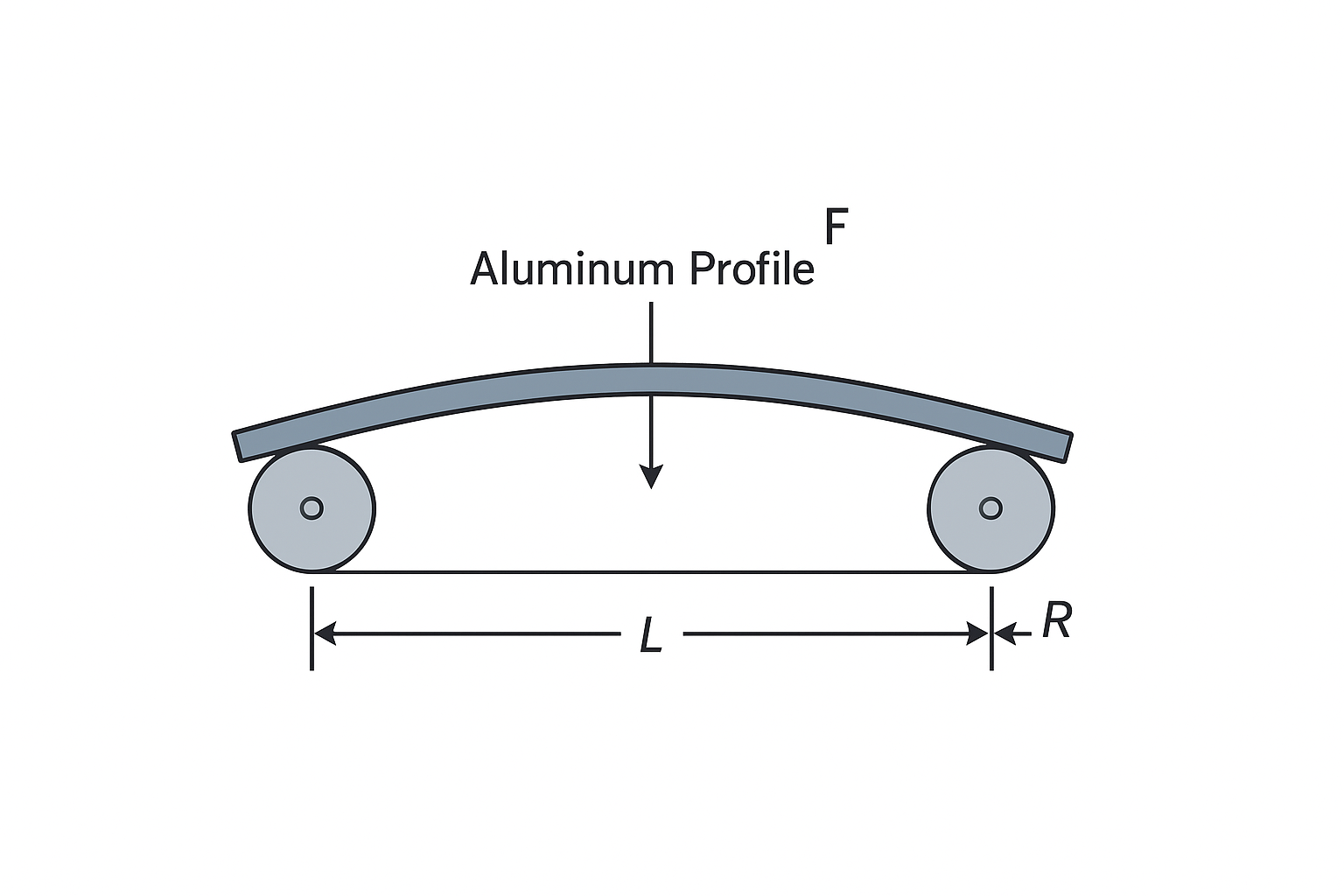

Aluminum Profile Roll Bending Force Calculator — Professional Edition

This calculator is designed for engineers who need precise roll-bending force estimations based on detailed section properties and material parameters.If you’re not working with structural calculations or simply want an easier way to check bending feasibility, we’ve also prepared a more user-friendly version.You can try the simplified calculator here:Aluminum Profile Roll Bending Calculator — Standard

-

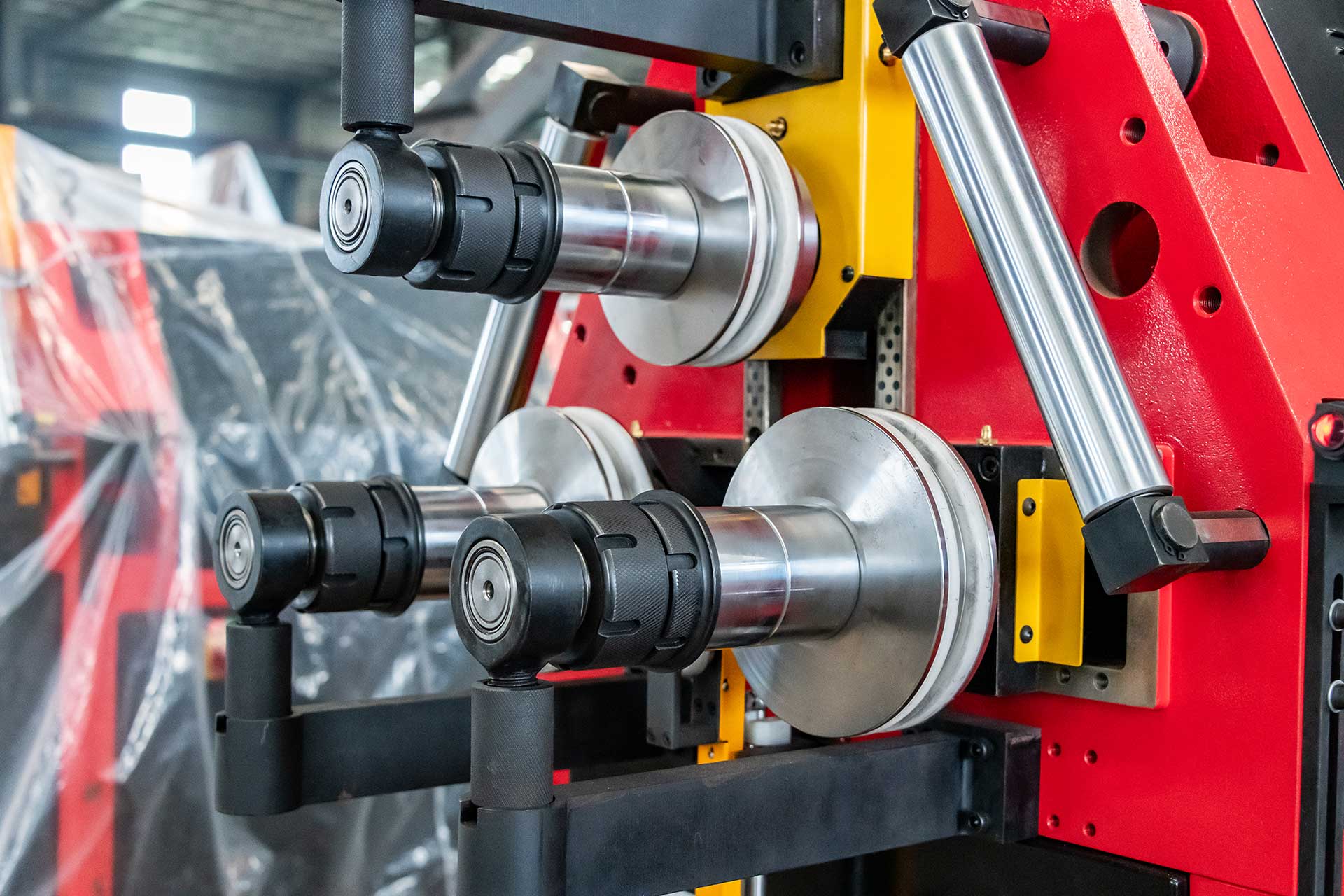

Aluminum Profile Bending Forming (2): Roll Bending

Roll bending of aluminum profiles is a forming method that bends the profile by means of rotating rollers. Section 2: Roll Bending Process Roll bending is a plastic forming process in which a set of rotating rollers gradually bends an aluminum profile into a specified shape. It is widely used in manufacturing circular structures, arc-shaped

-

Stretch Forming of Aluminum Profiles: Defects, Mechanisms, and Solutions

Stretch forming enables aluminum profiles to achieve complex, high-precision curvatures with enhanced structural strength and reduced springback. However, improper forming parameters can lead to defects such as fracture, wrinkling, surface distortion, and dimensional deviation. Understanding how stress states influence deformation and how to control process variables is essential to ensure reliable forming quality and cost-effective

-

Stretch Forming Aluminum Extrusions: Aluminum Profile Bending Process (I)

This is the first part of our series on Aluminum Profile Bending & Forming, focusing on the Stretch Bending Process. In this article, we explore how aluminum extrusions are bent using controlled stretching techniques to achieve precise curvature and dimensional accuracy. You’ll learn the principles behind stretch forming, its key advantages, and why it is

-

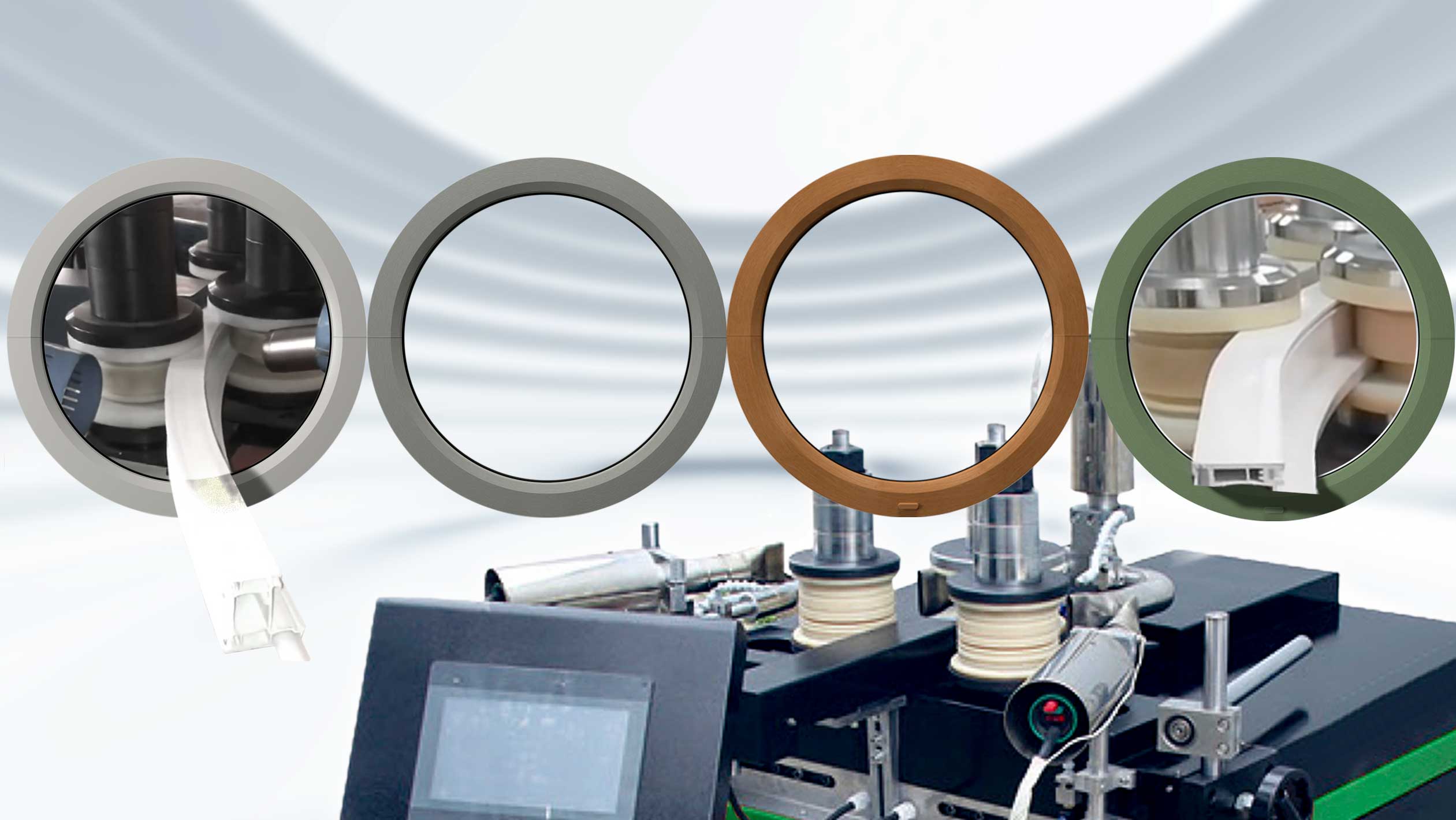

Aluminum Curtain Wall Profile Bending and Free Calculator

The bending process of curtain wall aluminum profiles involves high technical difficulty, mainly in several areas: Solutions of BIT To address the challenges of bending curtain wall aluminum profiles, the PBA aluminum profile bending machine offers several innovative solutions. First, for longer curtain wall profiles, the PBA bending machine is equipped with a powerful support

-

Bending Process and Key Considerations for Aluminum Tent Profiles

The stretch forming process for roof tent frames applies tension and bending moment at both ends of the tent profile, so that the aluminum tent profile is stretched and bent while wrapped around the forming die. This can effectively reduce the bending rebound and improve the contour accuracy of the tent profile. It is particularly

-

Steel vs. Aluminum Roll Bending: 4 Key Differences

Roll bending of steel structural profiles and aluminum extrusion profiles differs significantly in material properties, process control, and equipment requirements. These differences directly impact the bending force selection, deformation behavior, and precision control. Material Properties Steel structural profiles have higher strength and yield points, requiring greater bending force. In contrast, aluminum extrusion profiles are softer

-

Bending Aluminum Angle

There are many advantages to bending angle aluminum. Angle aluminum is light and strong, and it still maintains high strength after bending, which is suitable for occasions where weight reduction is required. An oxide film will form on the surface of aluminum, making it less prone to rust and suitable for outdoor or humid environments.

-

PBA aluminum profile bending machine for bending uPVC profile application

uPVC is an ideal material for window profiles due to its lightweight, durability, thermal insulation, and soundproofing properties. Imagine you are in the kitchen preparing a delicious dessert. You need to knead the dough into a specific shape, then bake it in the oven, and finally achieve a perfectly curved loaf of bread. This process

-

The Bending Radius in Aluminum Bending

The bending radius is a key parameter in aluminum bending, directly affecting the quality and precision of the process. This article highlights the principles of bending aluminum, the factors influencing the bending radius, and how to select and calculate the radius using advanced aluminum bending machines. Principles of Bending Aluminum Bending aluminum involves using mechanical

-

Key Factors for Aluminium Window Bending

Aluminium Window Bending can be one of the simplest methods for shaping aluminum profiles. However, the process can present challenges, depending on several critical factors: Simple Formula for Minimum Bending Radius The minimum Aluminium Window Bending radius can be calculated as:Minimum Bending Radius = Y-axis width × 5 Core Features of Aluminum Window Profile Bending

Home »